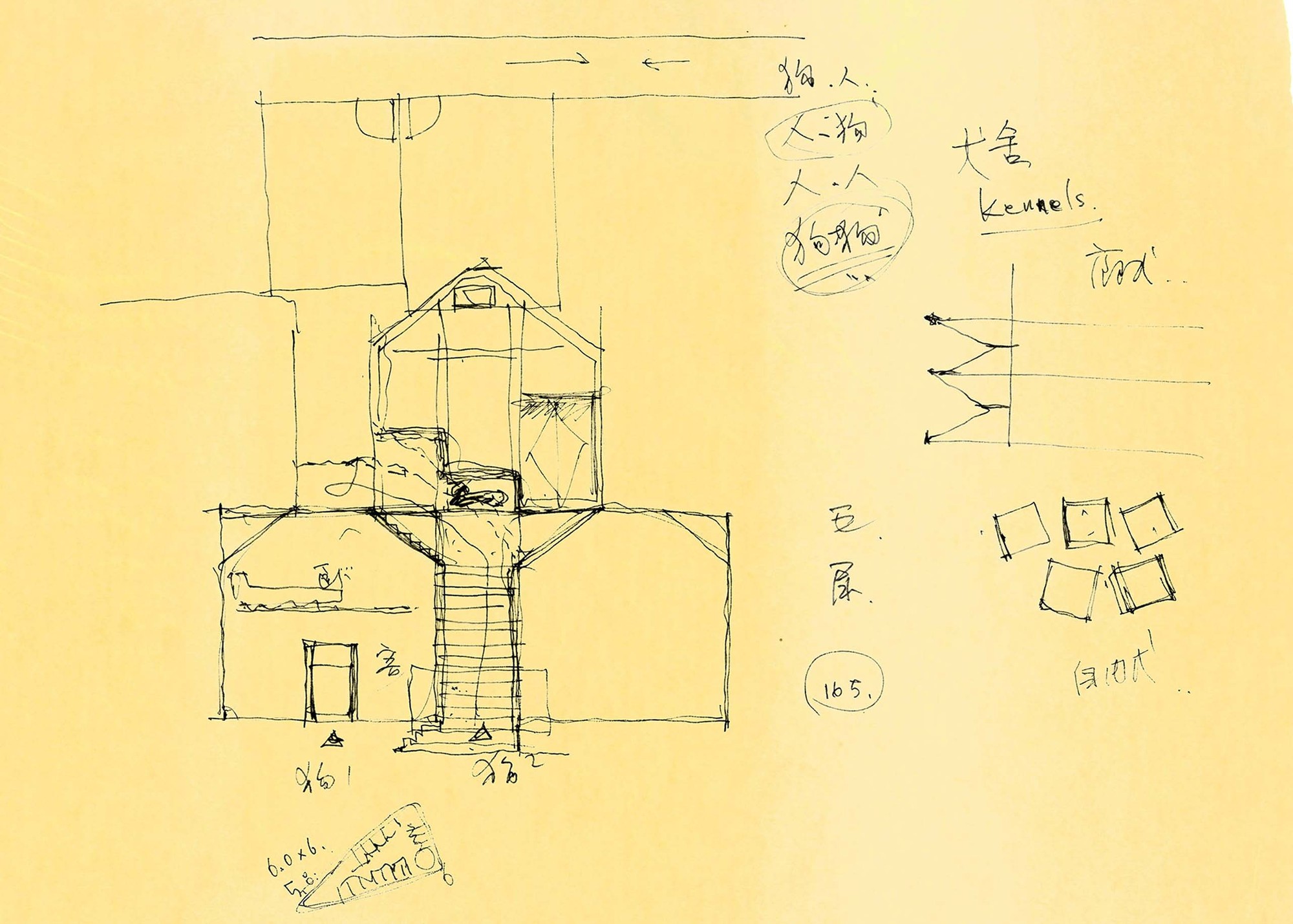

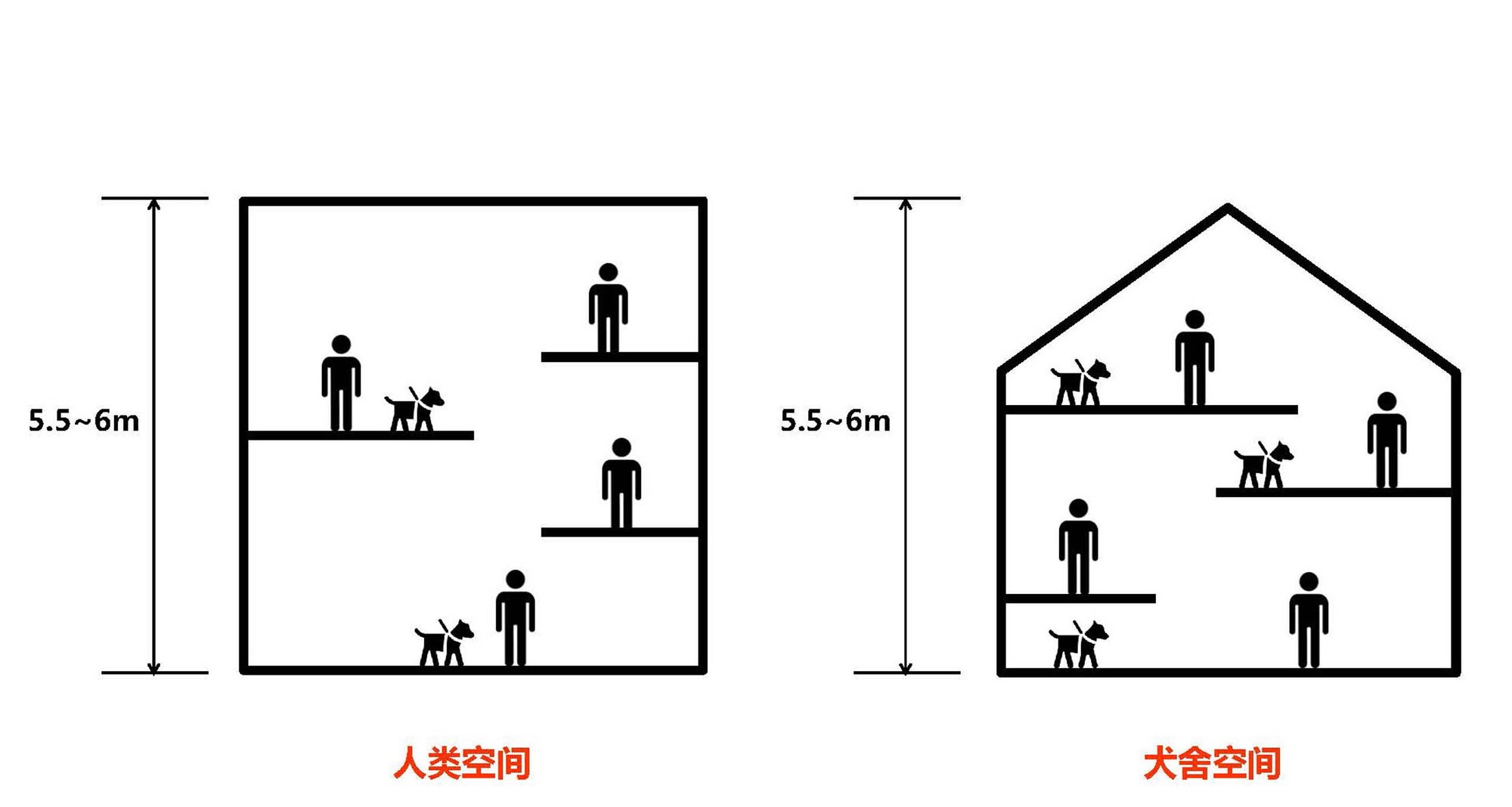

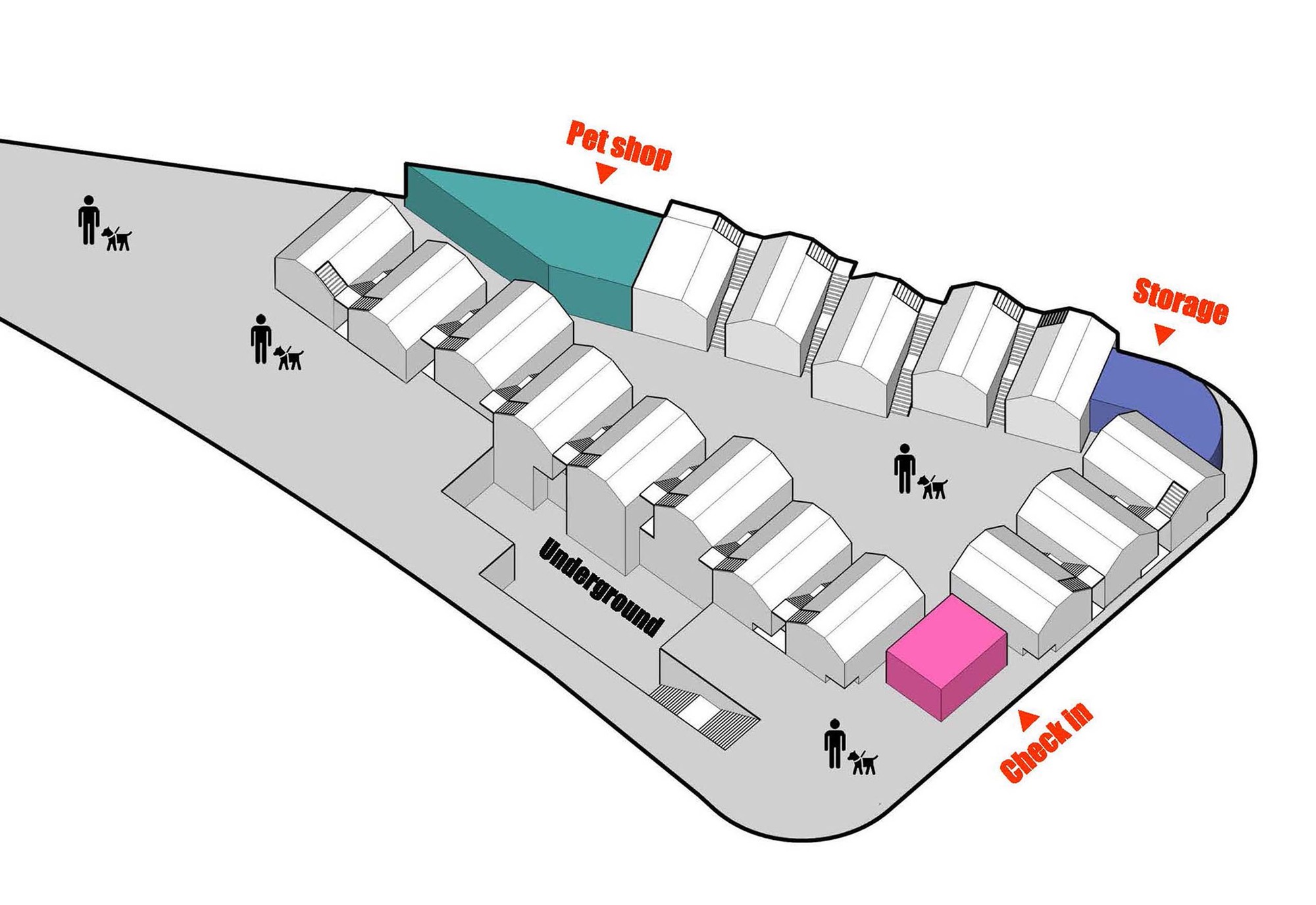

Project concept. The architect and client had been thinking about people and dogs ever since the triangular-shaped “corner” site at the southern-most of Aranya was defined as a pet hotel. Usually, the design model of a small hotel is either a low-rise veranda, or scattered detached building, or the very popular “one big pallet with a bunch of small boxes” complex. From human standpoint, these models are all feasible. But as anyone who has ever owned a dog knows, dogs are happy when they meet other dogs from time to time, but people are not happy because of the panic. Therefore, dog-to-dog encounters should be avoided as much as possible at non-essential times. So, at the beginning of the program, the porch layout was avoided, and there was some torn between freestanding and townhouse style.

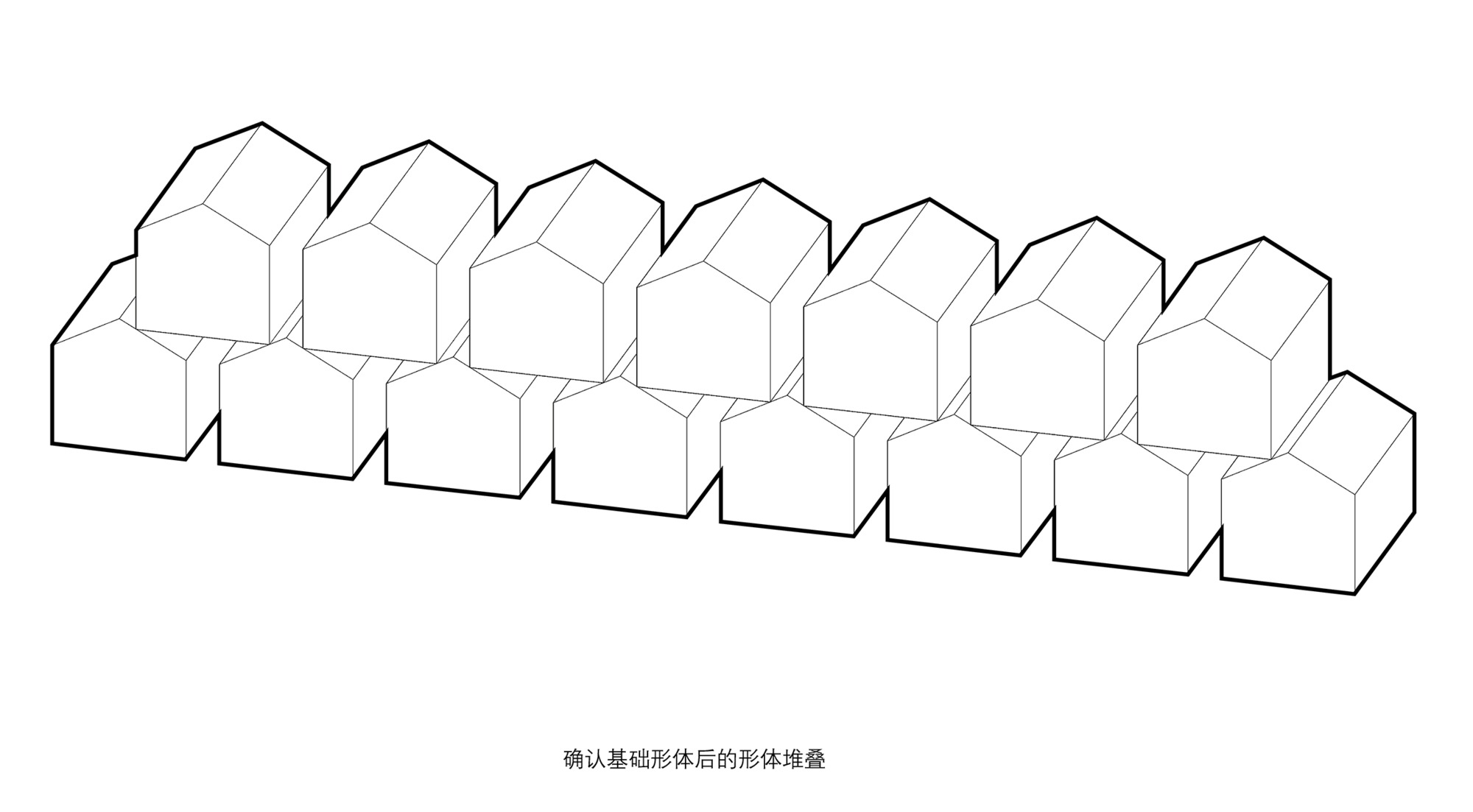

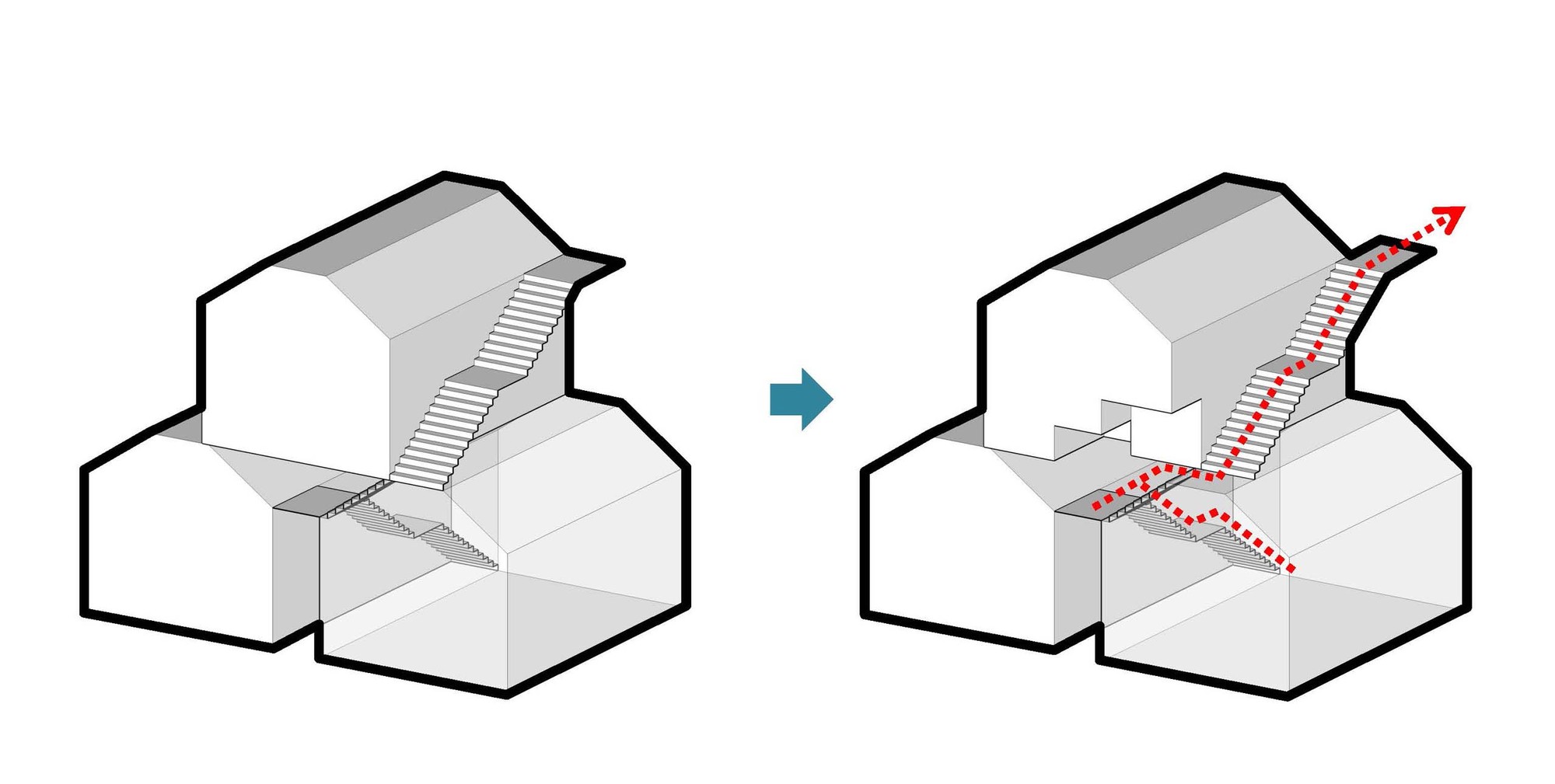

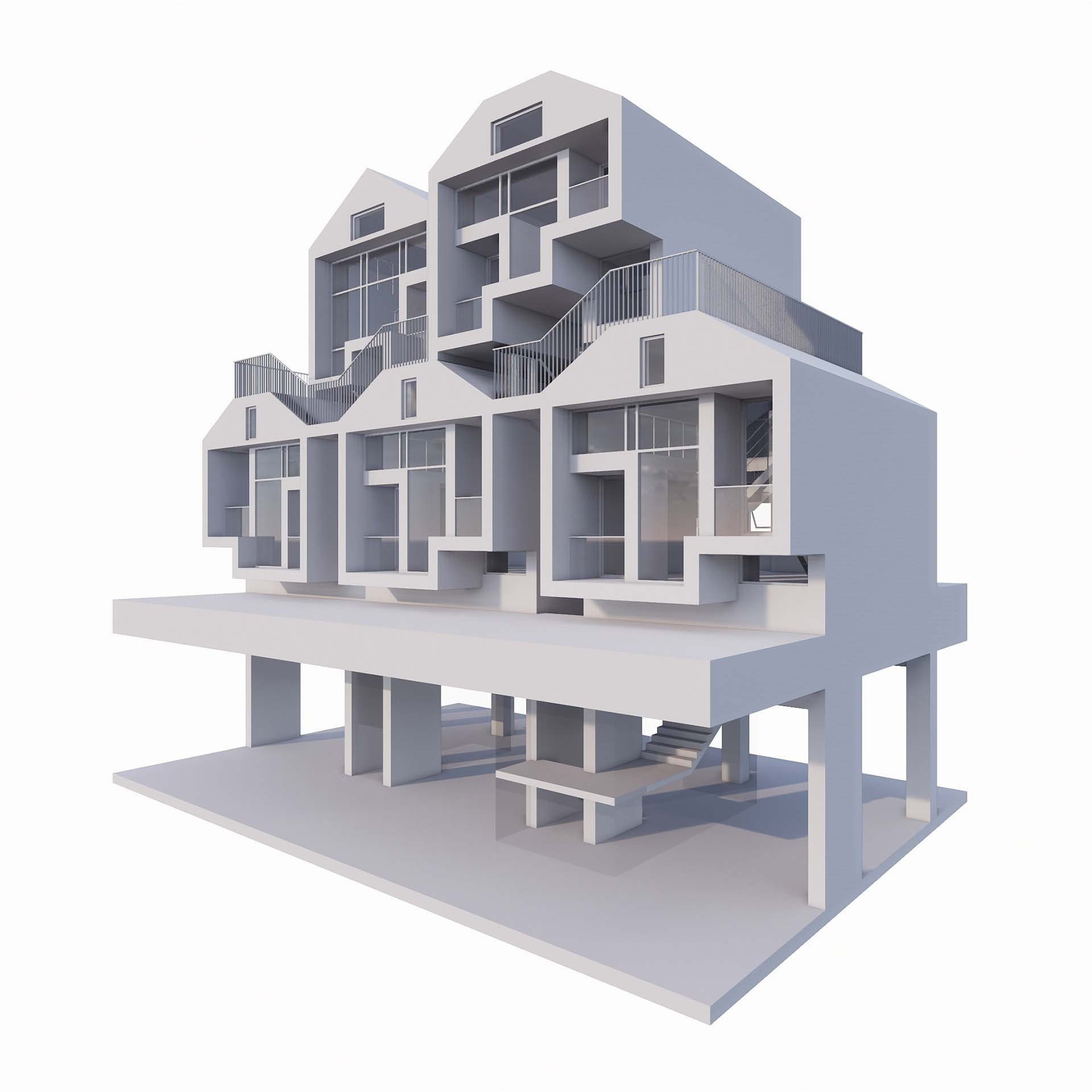

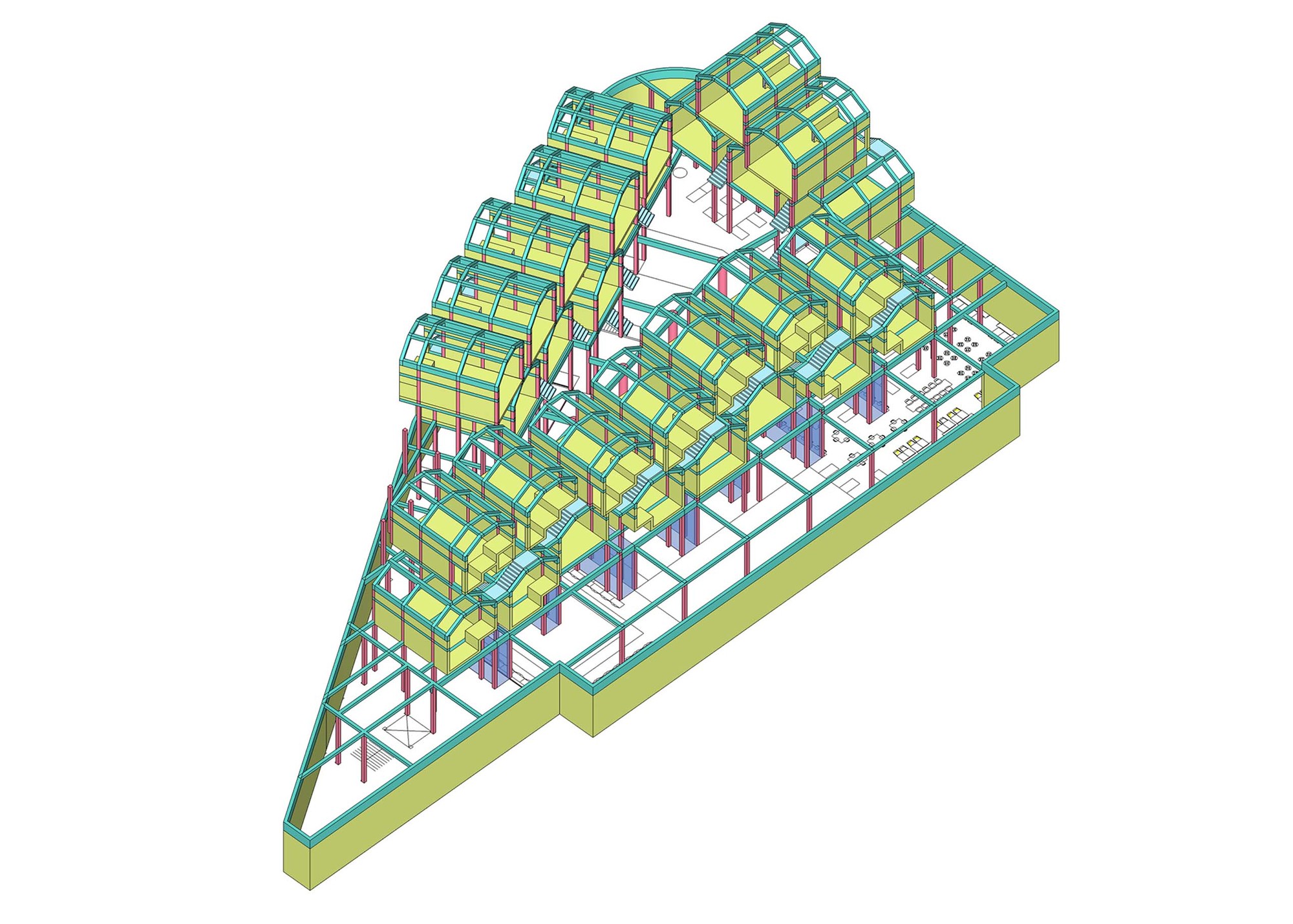

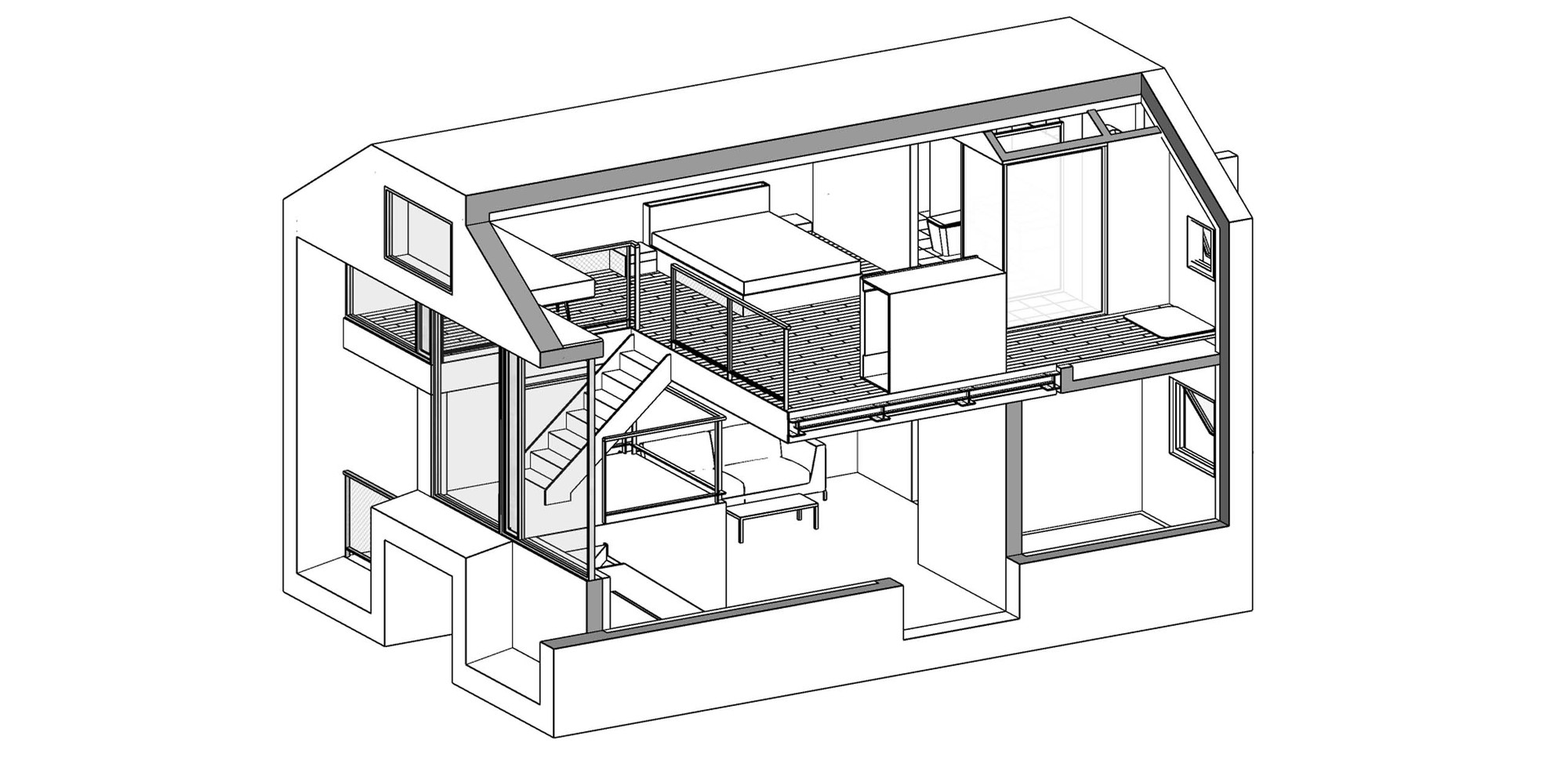

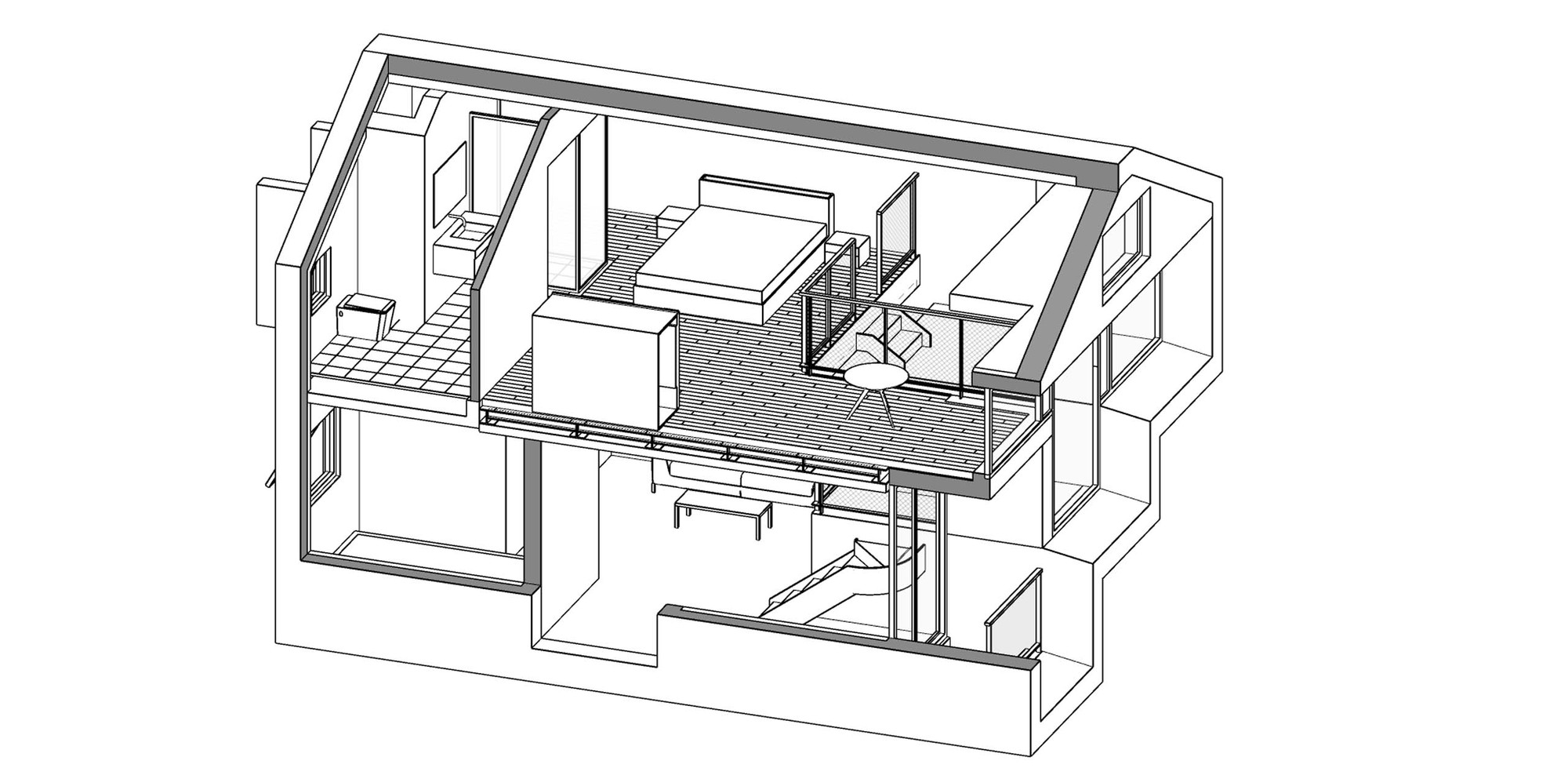

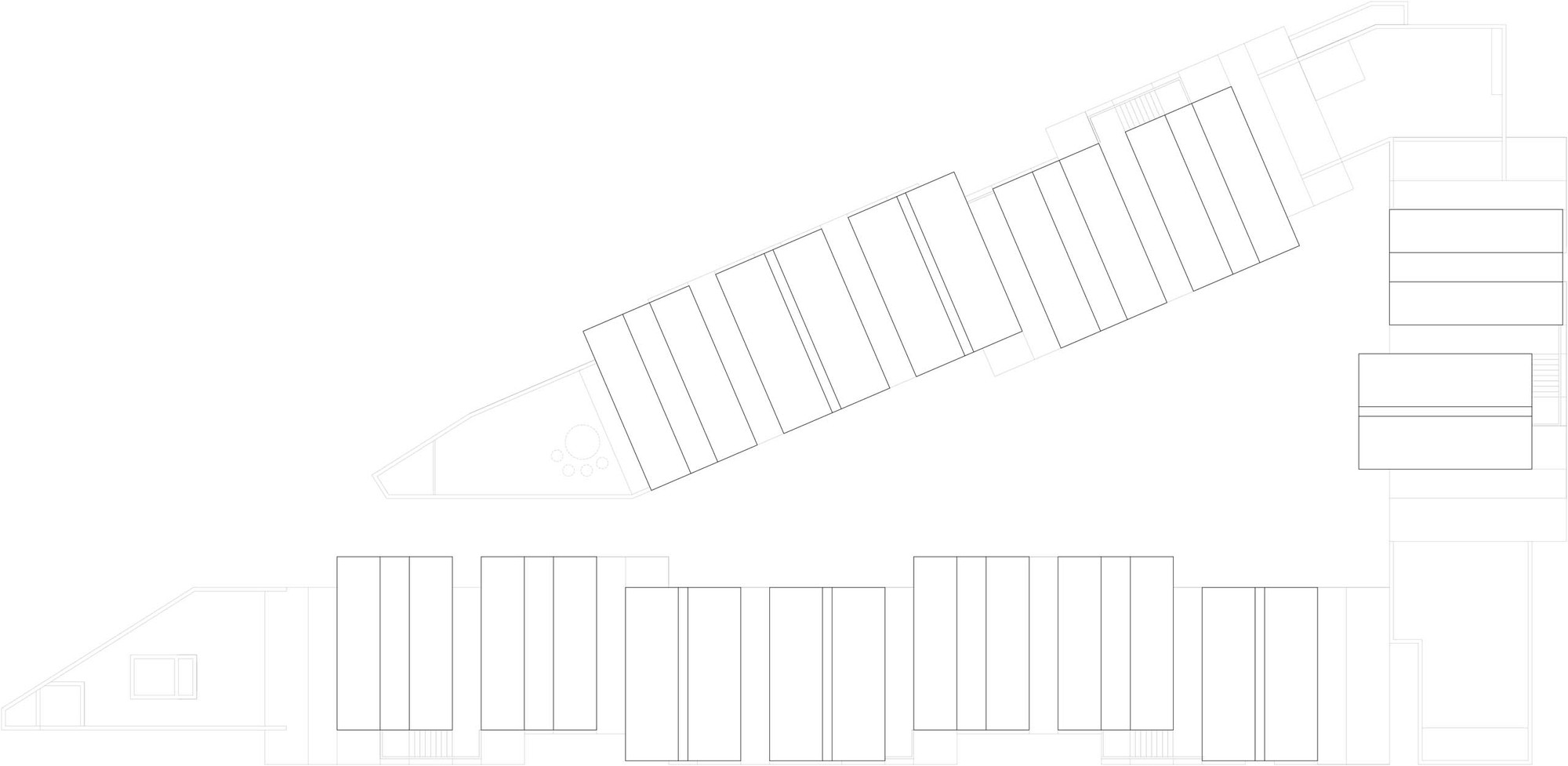

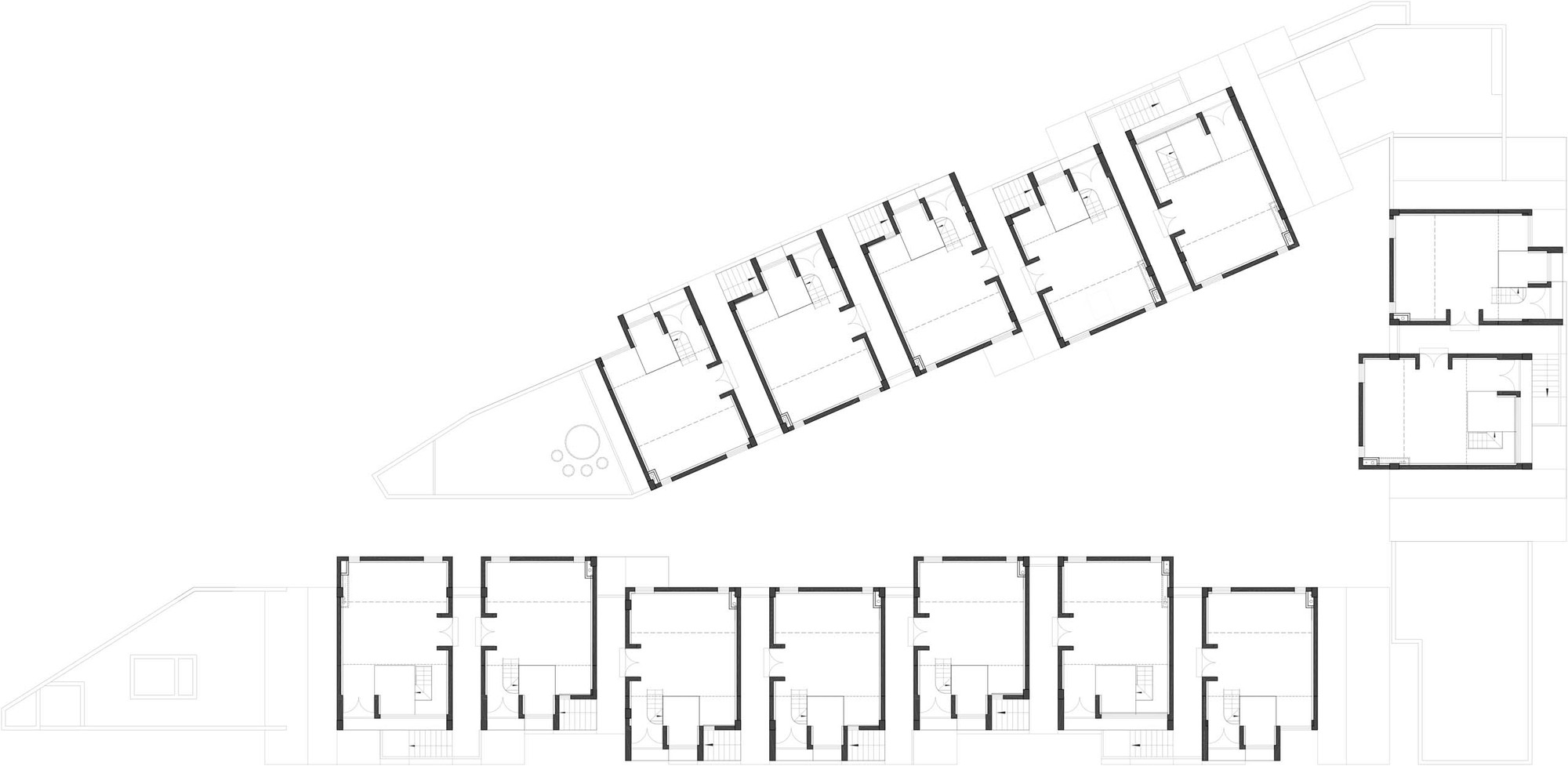

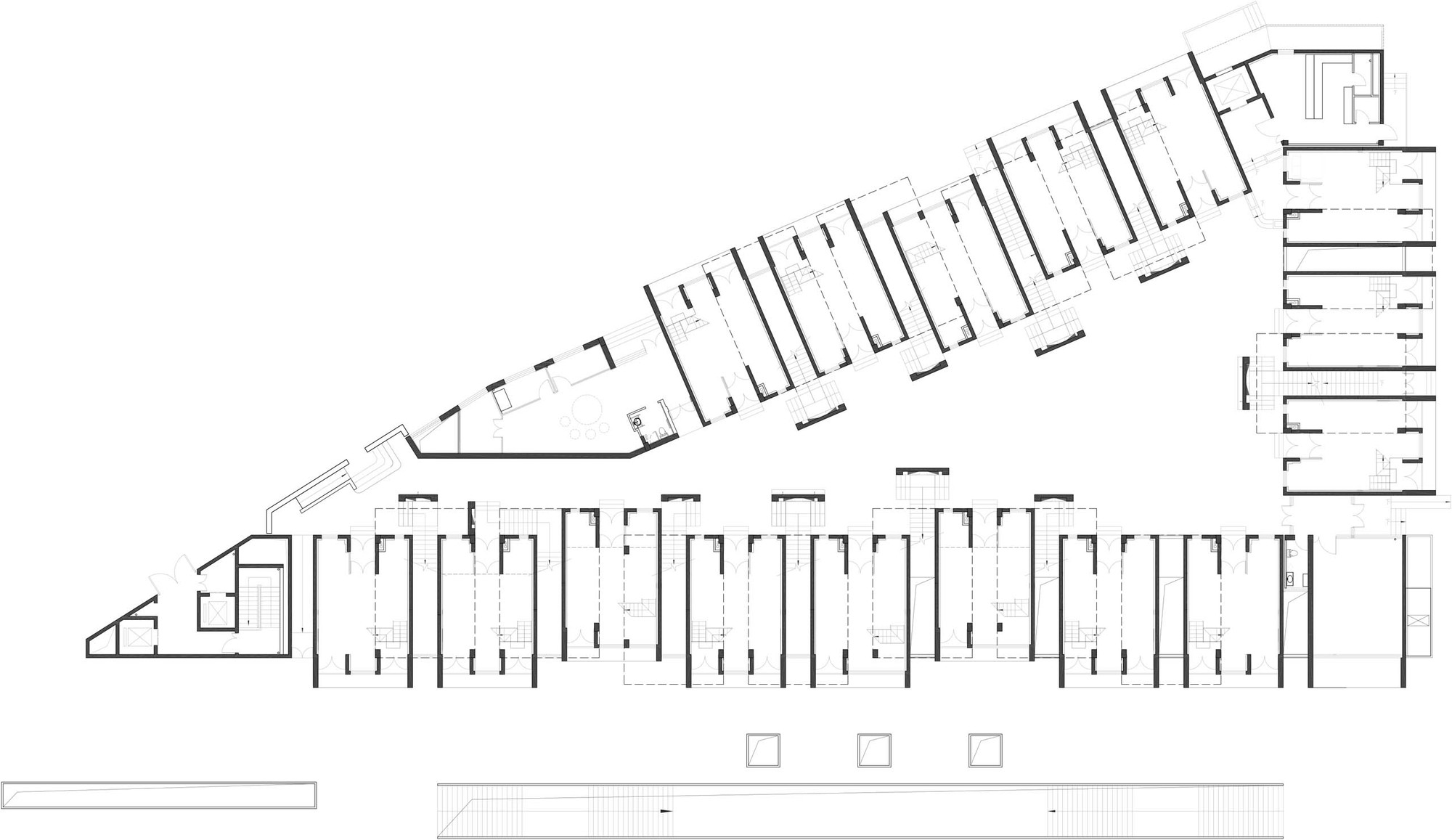

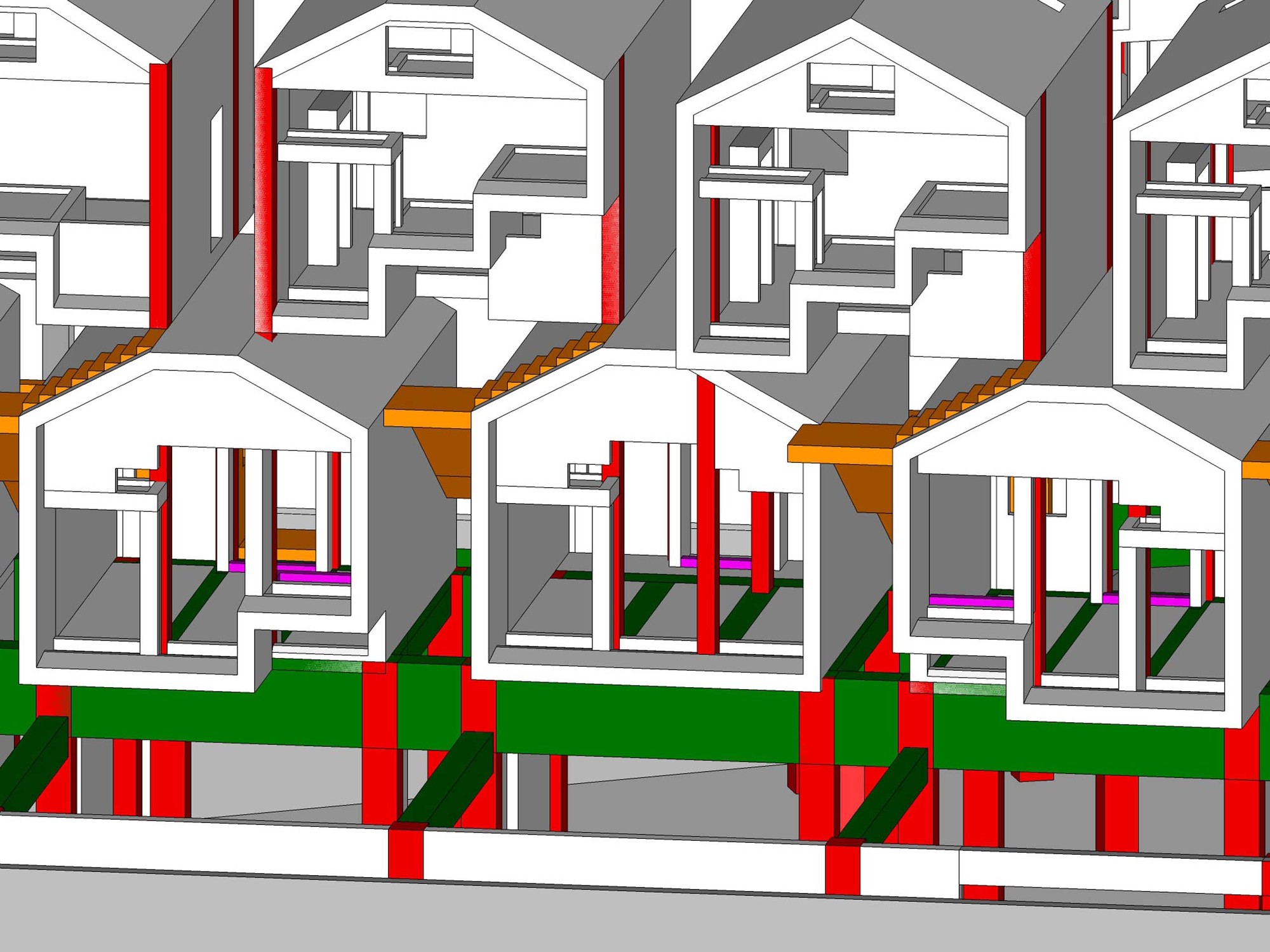

The characteristics of the two models were combined to design a staggered top and bottom stacked model with a total of thirty boxes. Entrances and exits are independently separated from each other, which creates a very different architectural shape in addition to solving this problem of excessive dog-to-dog encounters while pulling apart between the houses to deal with the stairs and provide natural lighting for the basement cafeteria. On the other side of the box, since forward and backward exist, some of the guest rooms create a drop-step façade shape in order to avoid the stairs, while also providing the basic frame for the leap stairs in the interior of guest room.

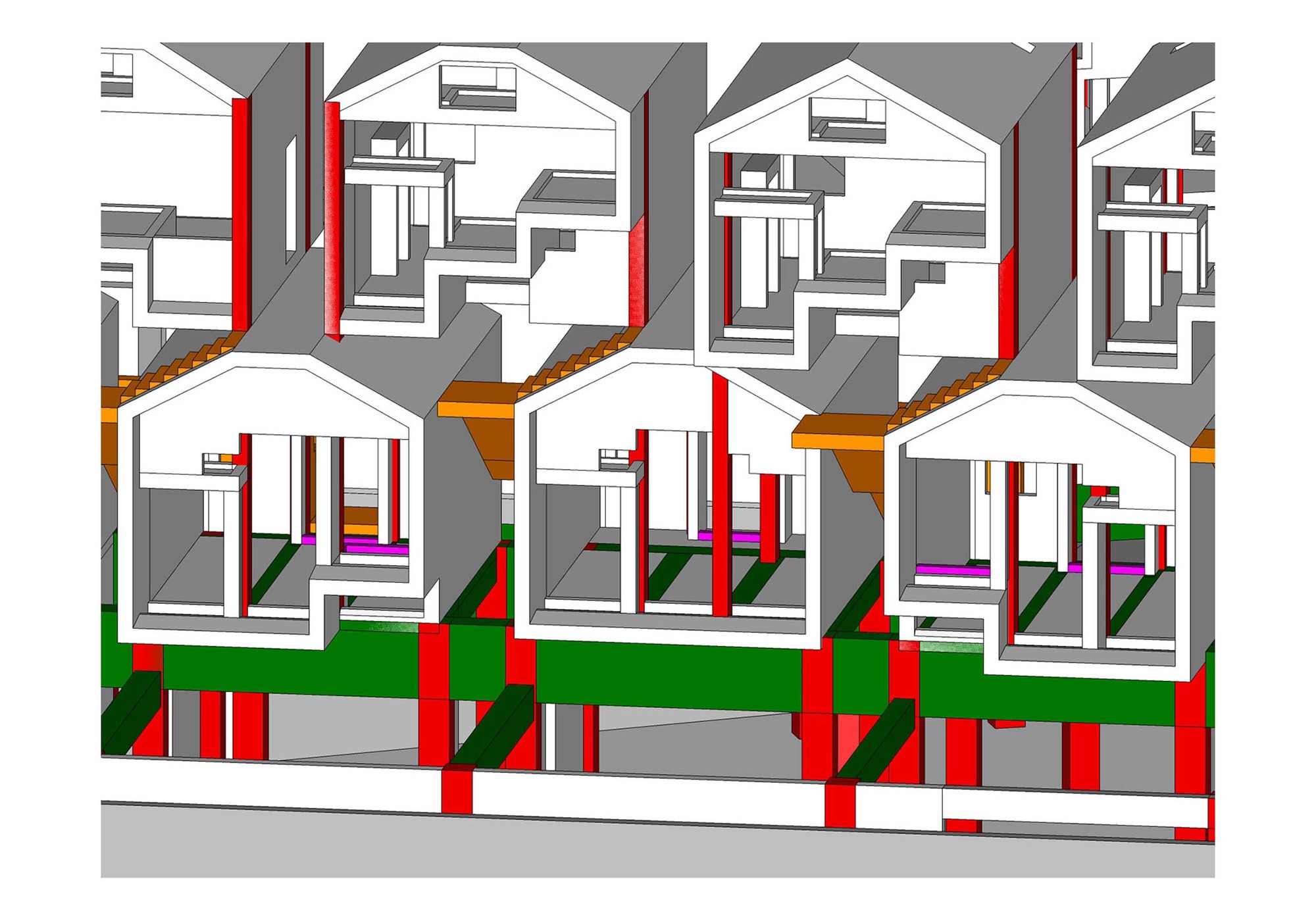

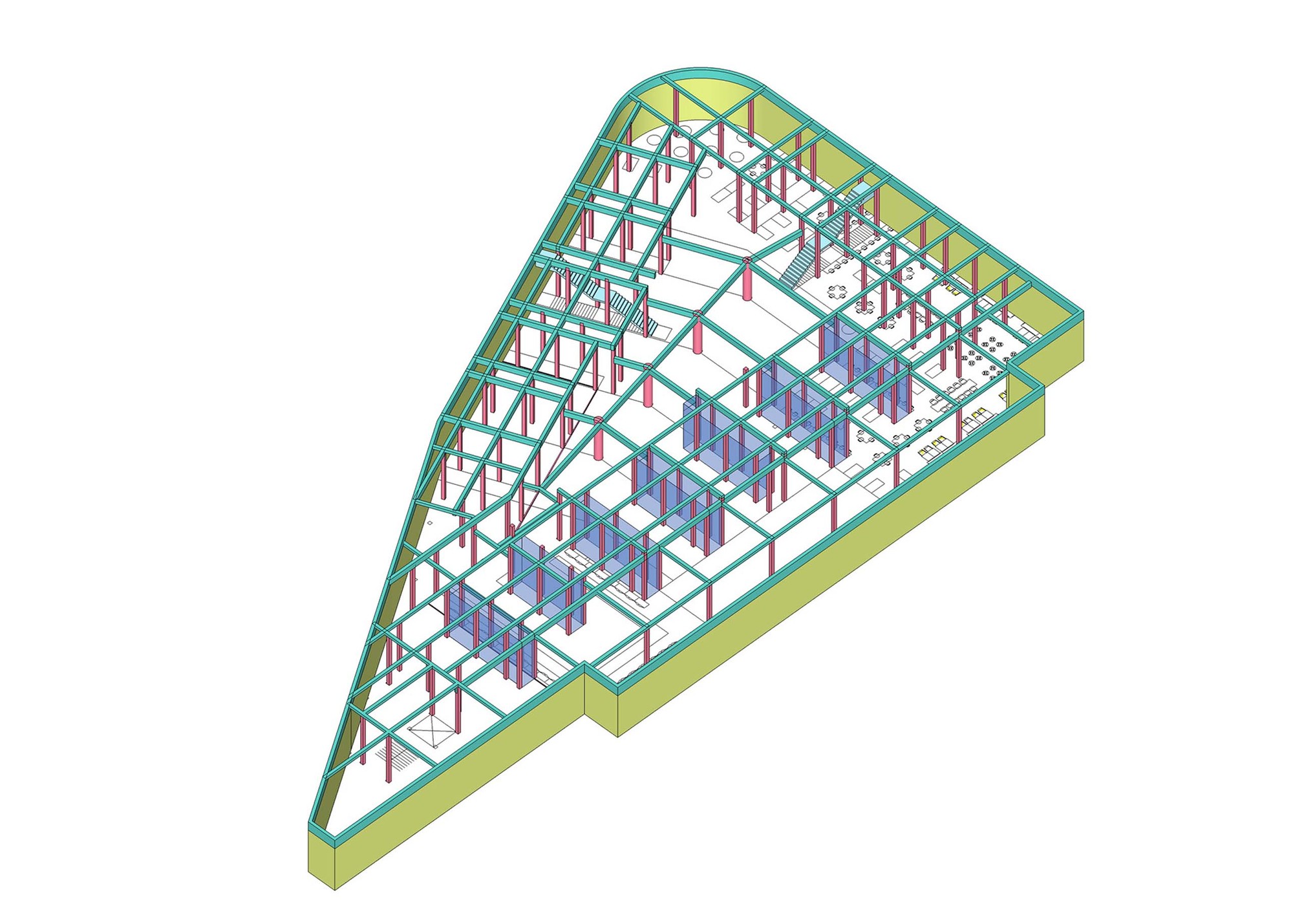

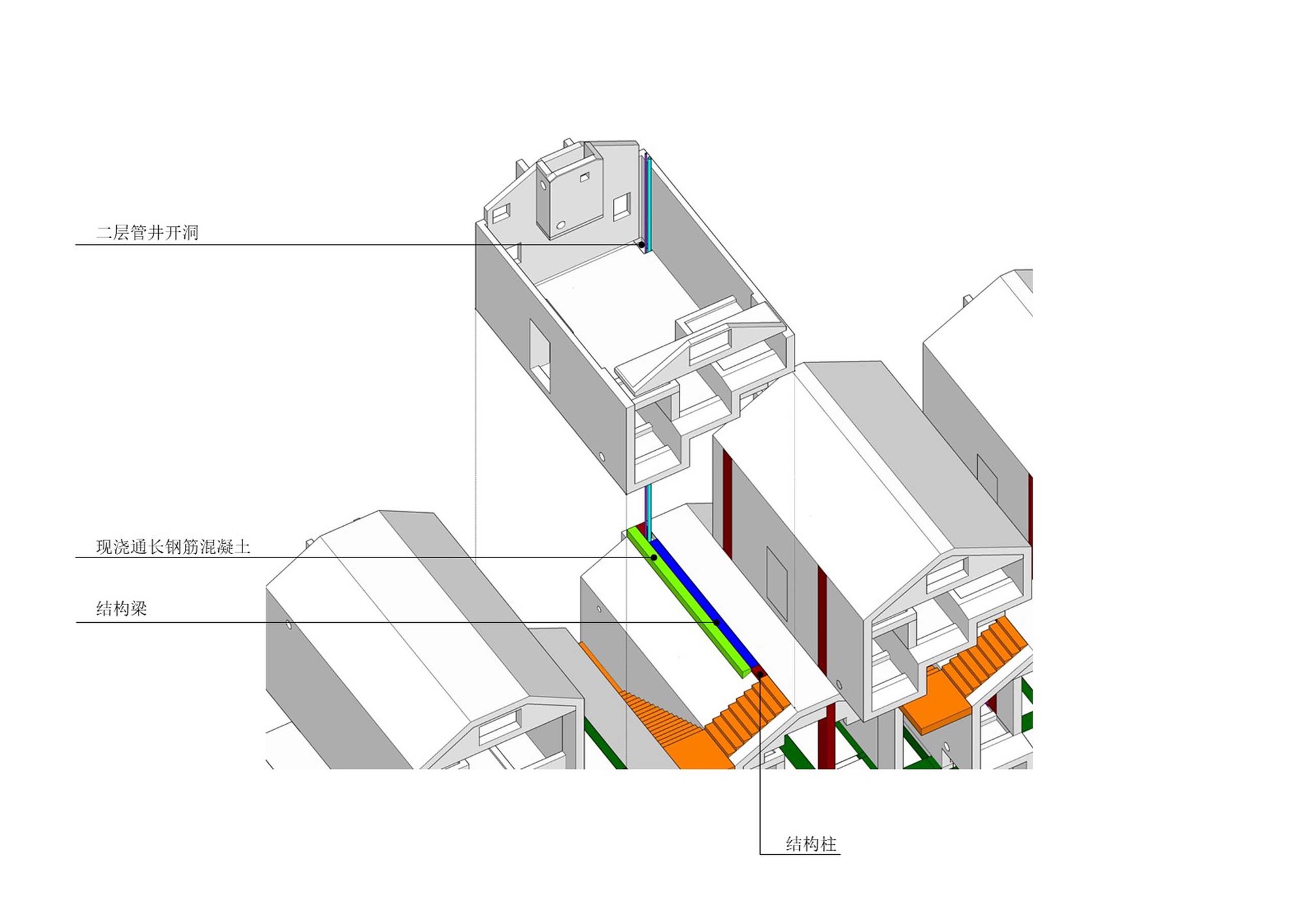

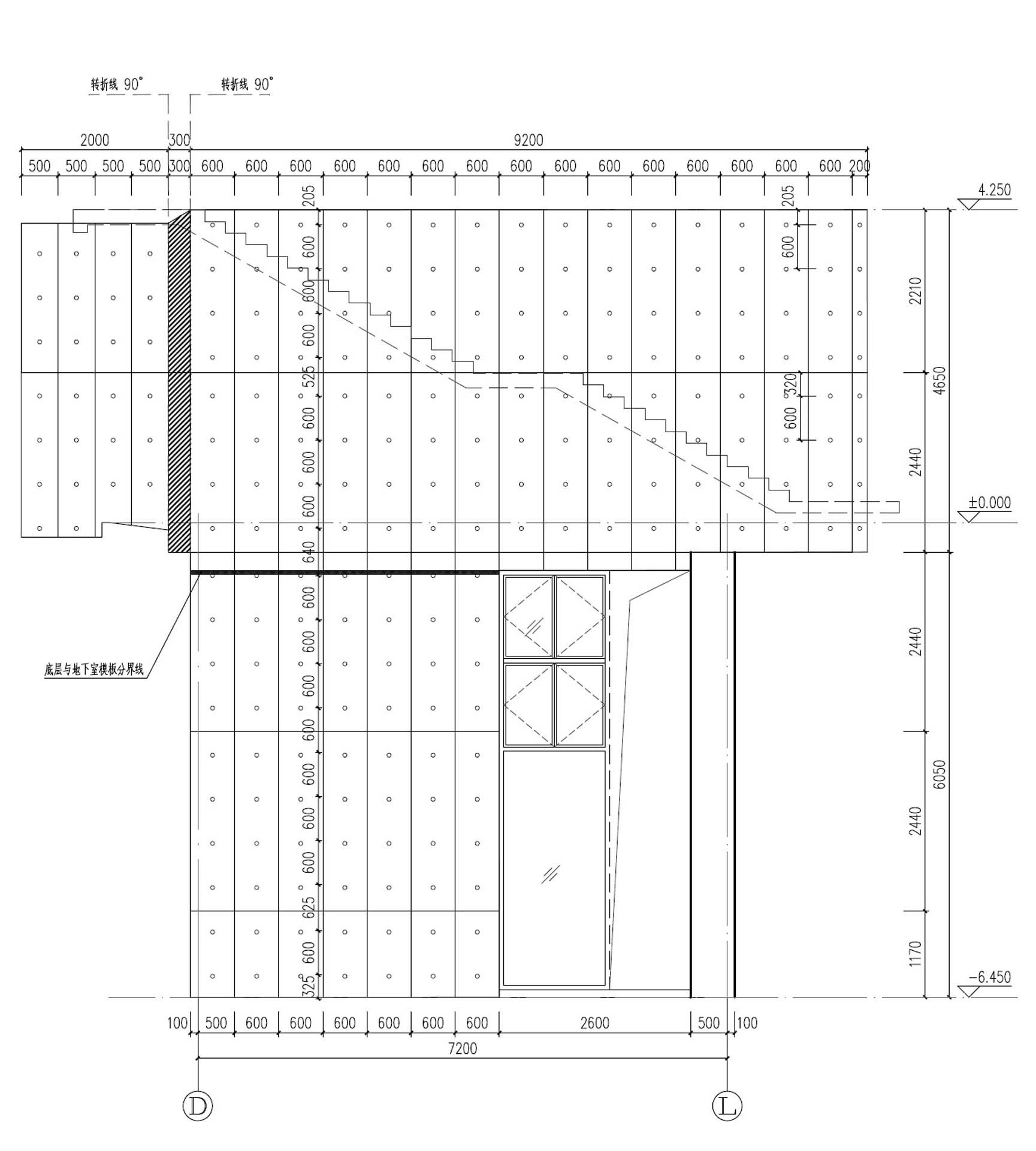

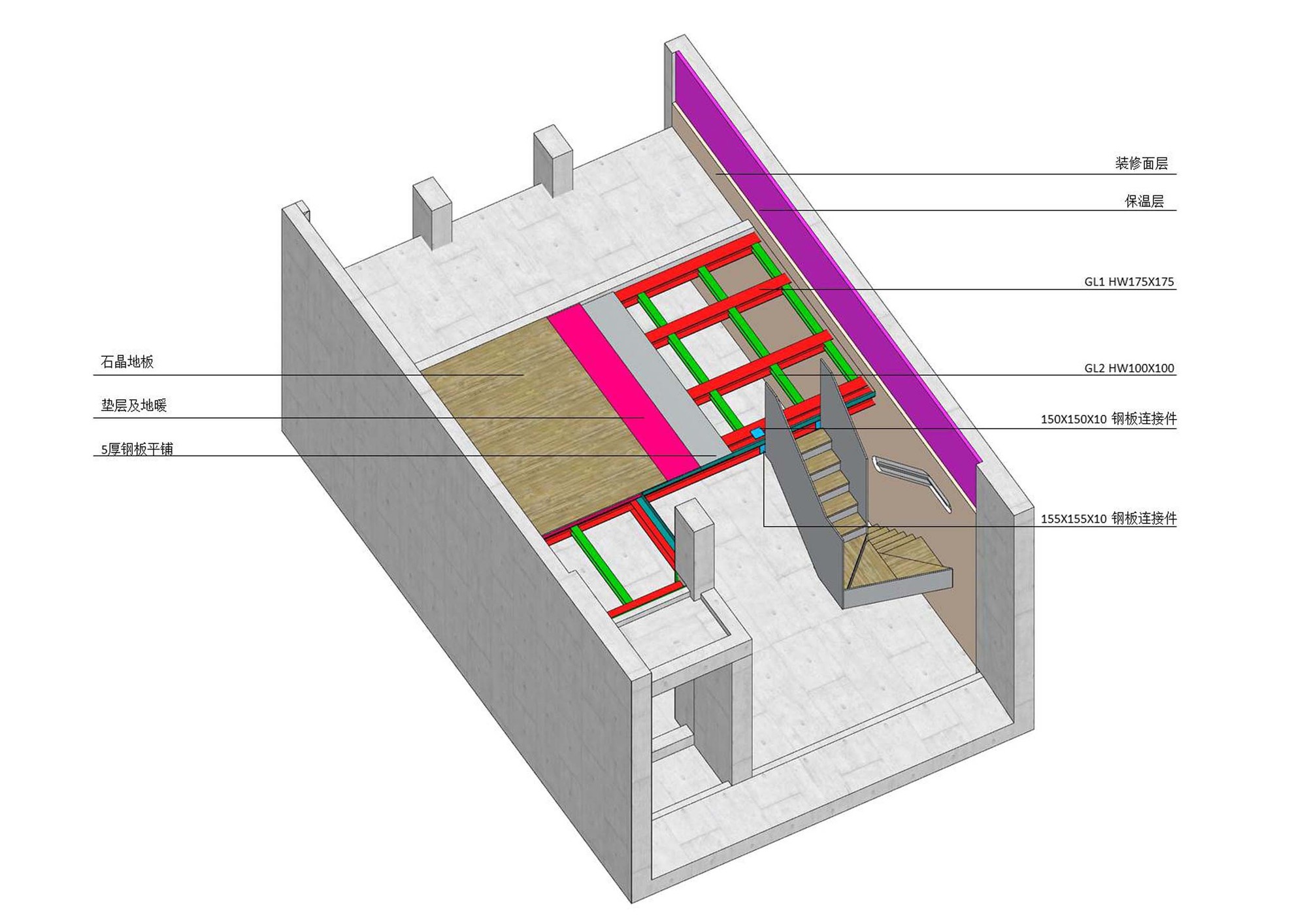

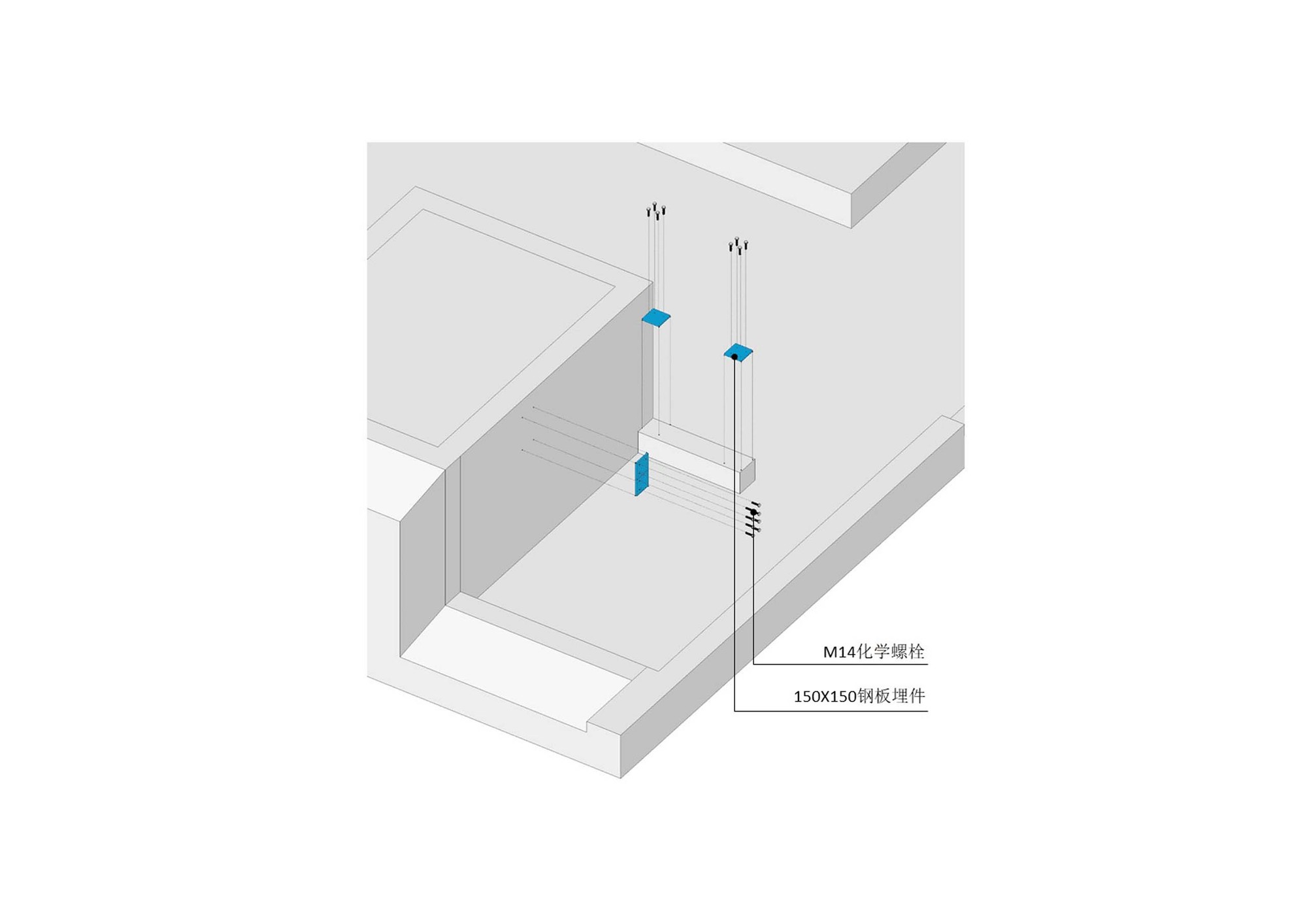

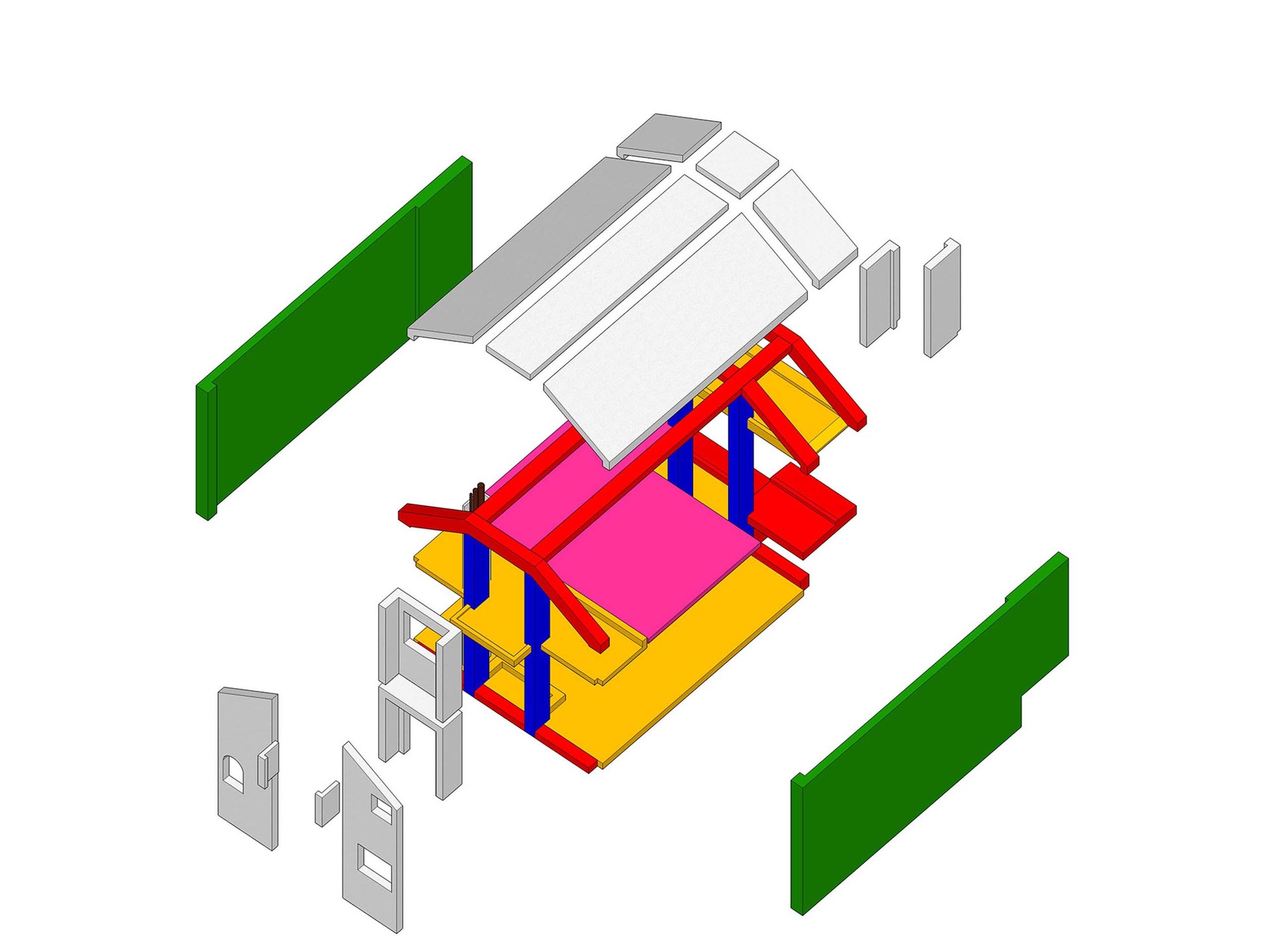

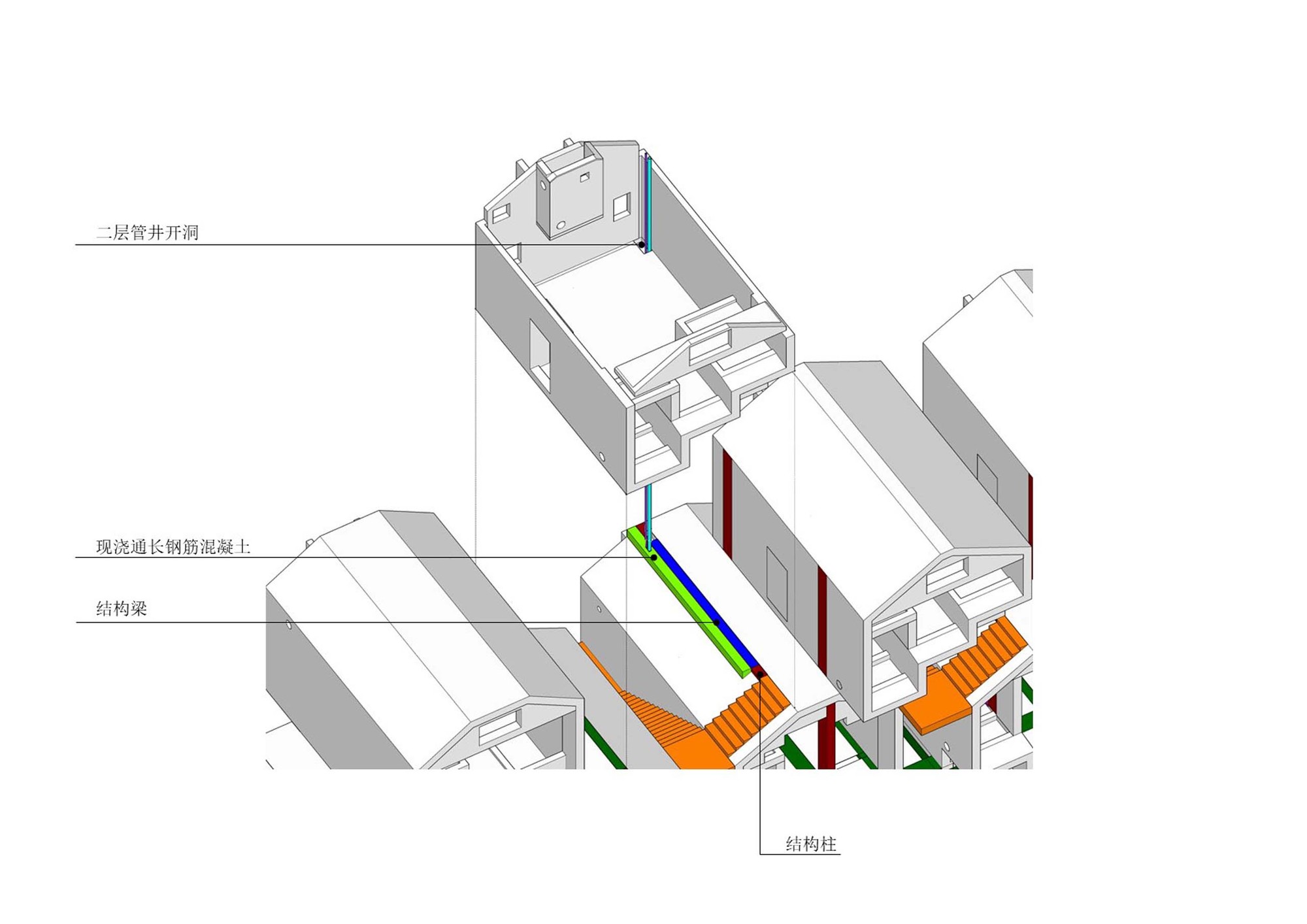

Structural design. Architects who pursue perfection have an almost fetishistic pursuit of the construction logic of spatial forms, that is, this kind of non-frame building shape does not want to appear in the initial design of the structure of aligned frame columns, but preferably all by the slab structure (hating beams and columns and obsessed with thick plates, a unique preference of the architects and I don’t know since when it was started). The vertical shear walls and diagonal structural roof panels form a box laminated “slab frame”, as suggested by the original structural consultant, Zhang Zhun. Although perfect, this non-aligned structural system requires high design and construction requirements, as well as structural overrun review of construction drawings, which is time-consuming and not always possible. Considering that I did not take the job of a “small spiritual building” where Ma Yin did not care about time and cost, but a commercial building which time and cost were important, I hesitated and gave up the so-called extreme pursuit of architects and chose the hidden frame structure, using the tiny overlap of the upper and lower boxes to Find the position of the frame column, and then use some architectural ways to make the column basically fade into the space of the lower guest room. The above-ground frame part is only structurally transformed at the basement roof slab.

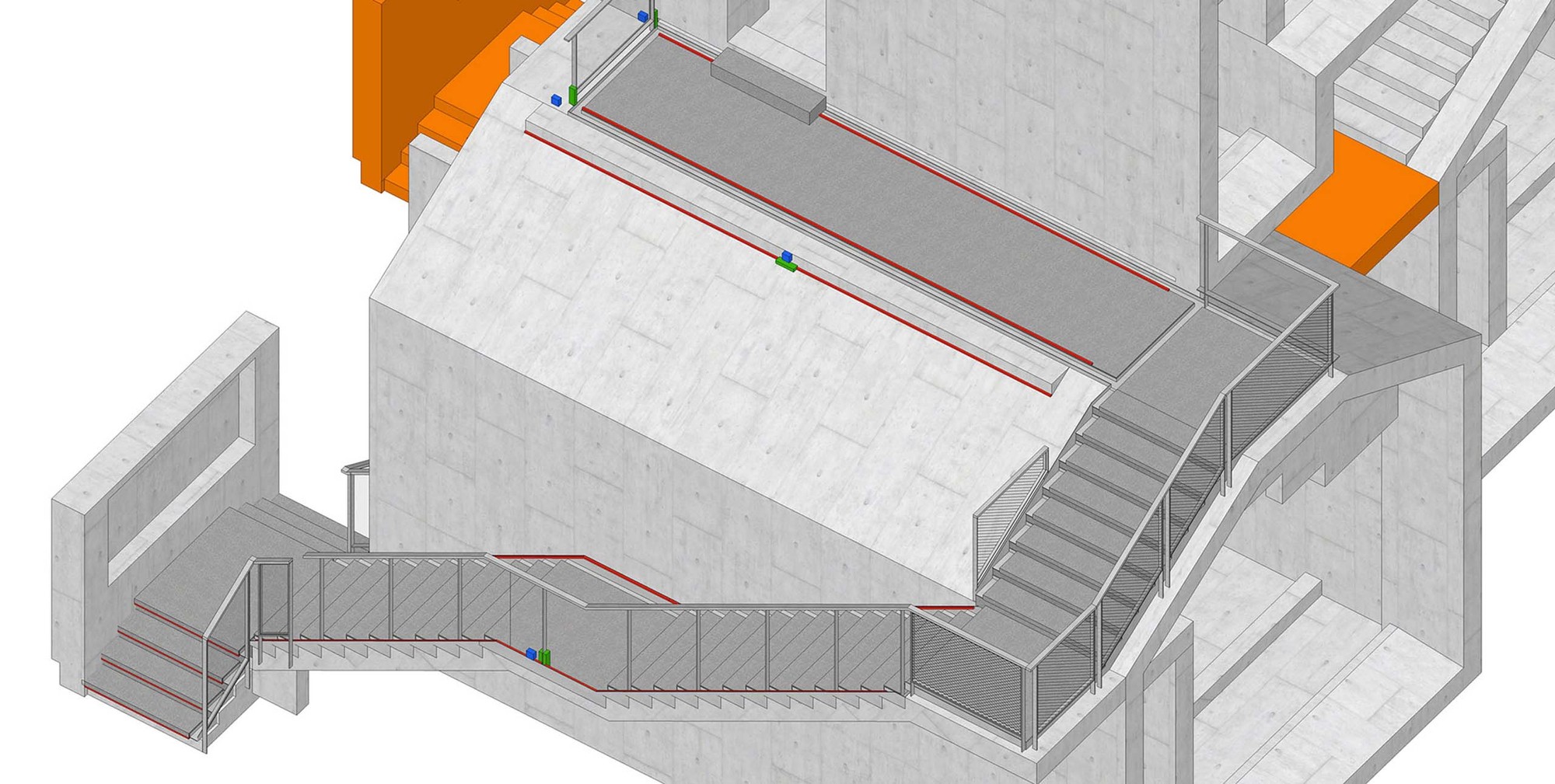

Equipment piping and drainage design. Since the overlapping part of the upper and lower guest rooms is very small, and the through frame columns have to be solved, the space to provide the pipeline aligned with the upper and lower is very narrow. In this narrow space, we have to solve the pipe shafts with insulation requirements, and at the same time, in order to avoid seeing too many overlapping parts on the facade and to keep the sense of separation between the upper and lower volumes, we recede the outer edge of the pipe shafts a little bit inward and hide them in the shadow, so that the overlapping of the upper and lower volumes will appear to be still lightly. At the same time, in order not to notice this abrupt tube well when going up the stairs, we poured an extra-long triangular beam, so that the so-called “cover-up” will not be noticed much.

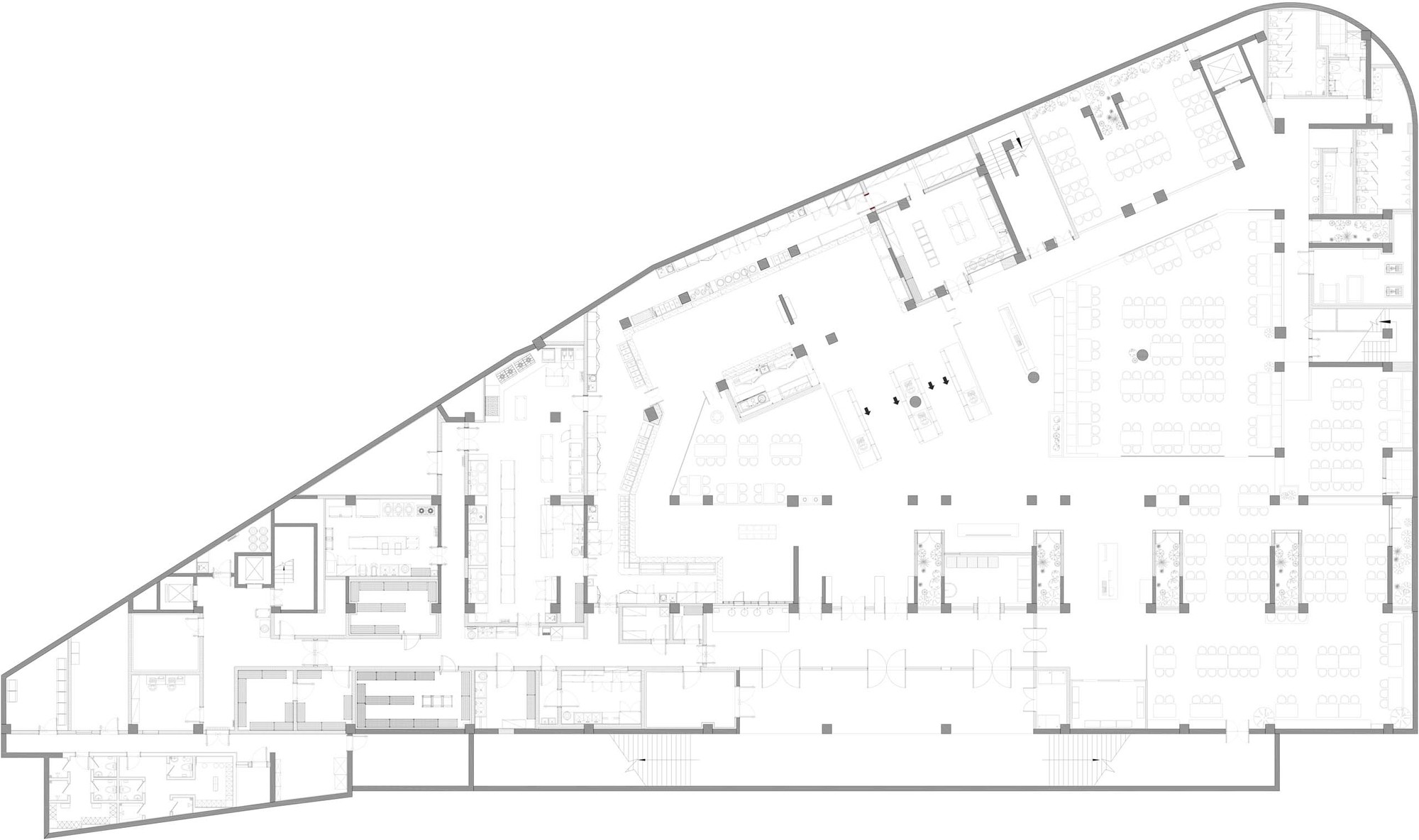

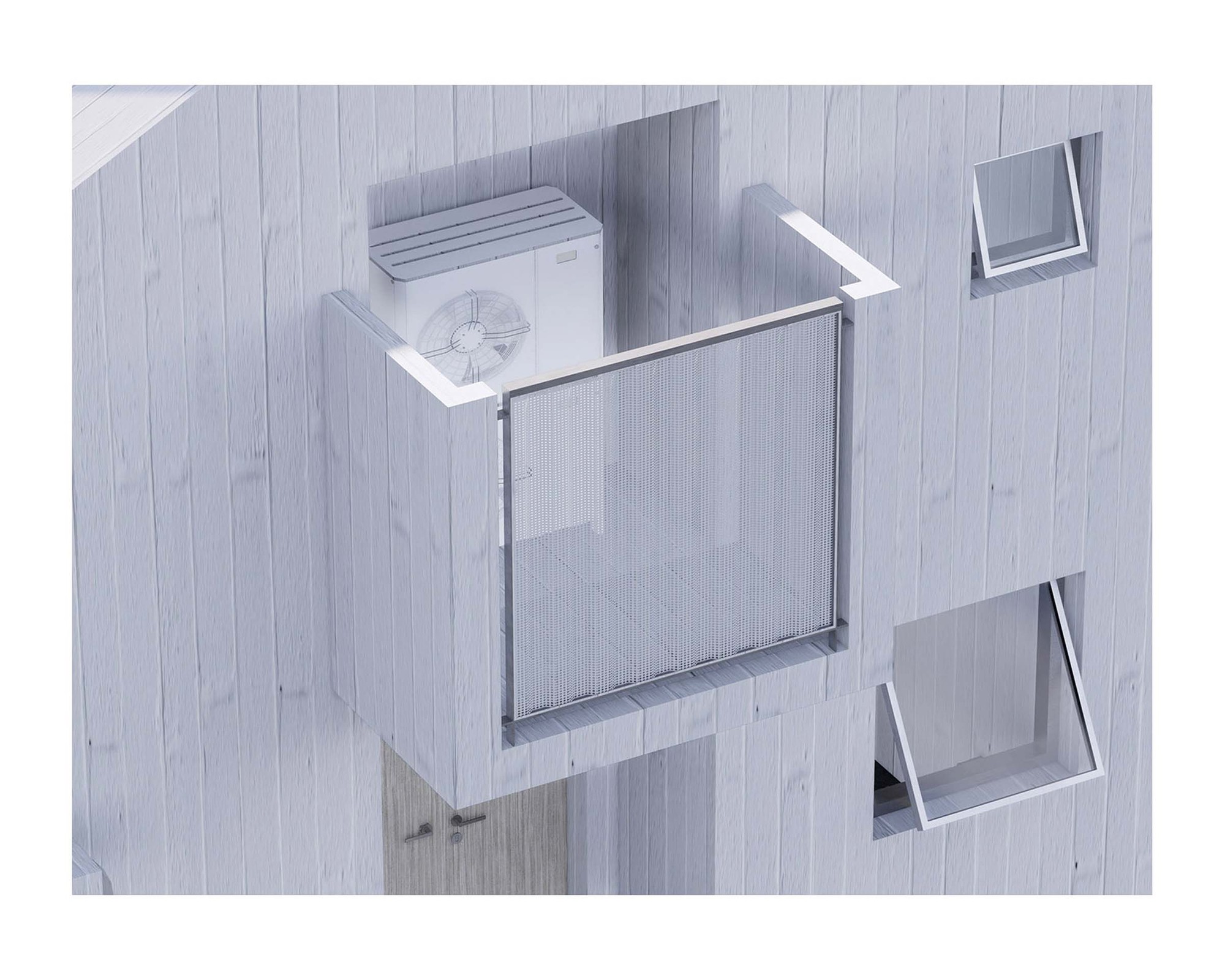

The rooms are supplied with centralized hot water, but each room is equipped with an independent VRV air conditioning system. The location of the external unit is generally the more invisible the better, but we did the opposite this time by deliberately enlarging the equipment platform, not only to dissipate sufficient heat but also to facilitate future maintenance and installation, and at the same time to provide a canopy for the ground floor entrance, which itself has become an important architectural symbol of the inner courtyard space.

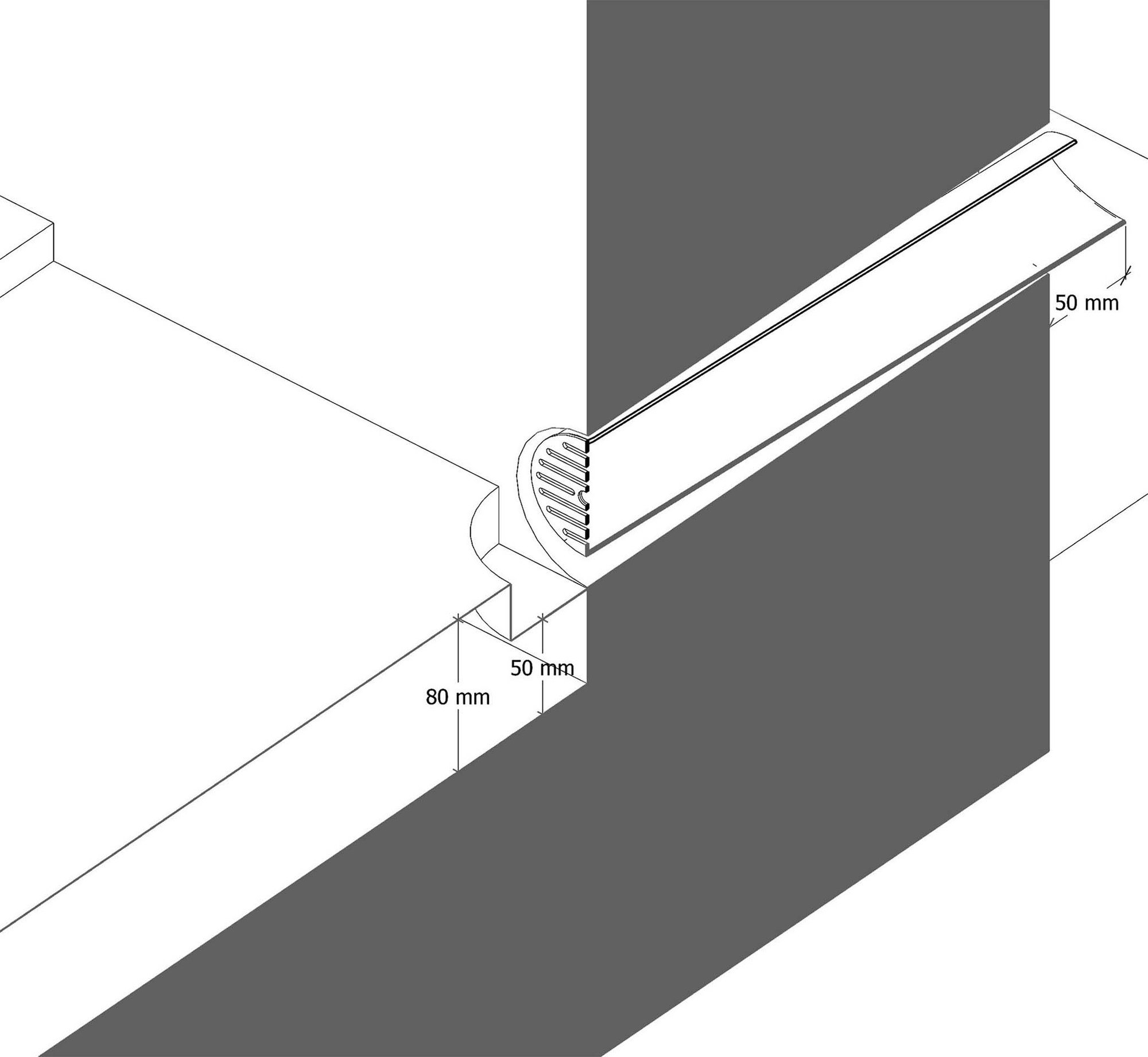

Due to the specificity of the shape, we adopted the design of free-falling water, the rainwater from the roof is discharged through the narrow ditch reserved on both sides of the second-floor access and staircase, and the condensation and frost water from the equipment platform is discharged freely by the metal rainwater outlet located at the corner of the wall in a position that does not affect people walking.

The lightning protection design, lighting design, and cafeteria equipment were all precisely considered to eliminate all factors that would have a negative effect on the building’s perception.

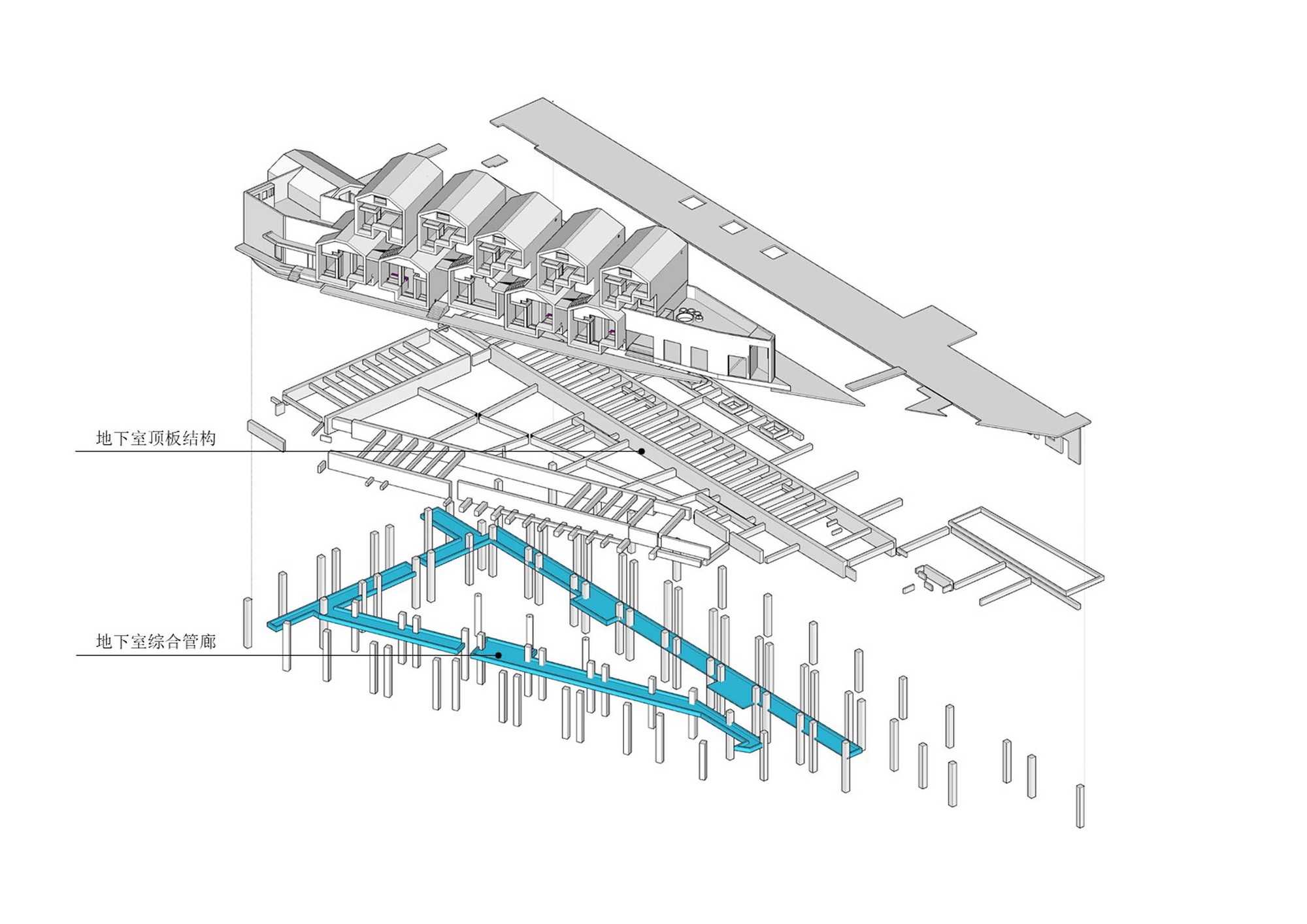

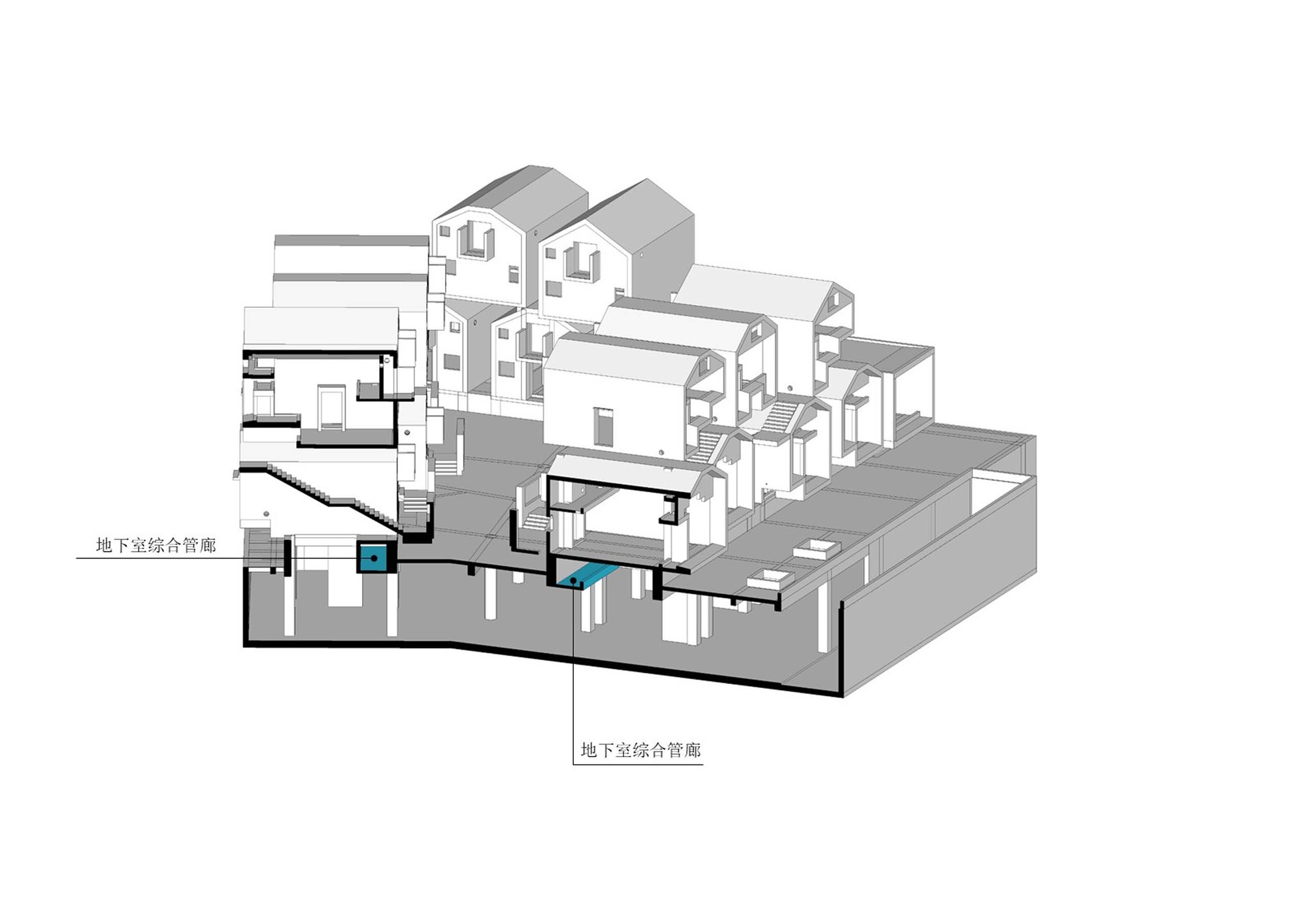

At the conversion of the tube well directly below the guest rooms, which is at the top of the cafeteria, a concrete integrated pipe corridor was reserved to loop through above the cafeteria based on our years of practical experience, in order to cope with a variety of unforeseen piping changes in the future, a foresight that served us well when the guest rooms were later converted to central heating.

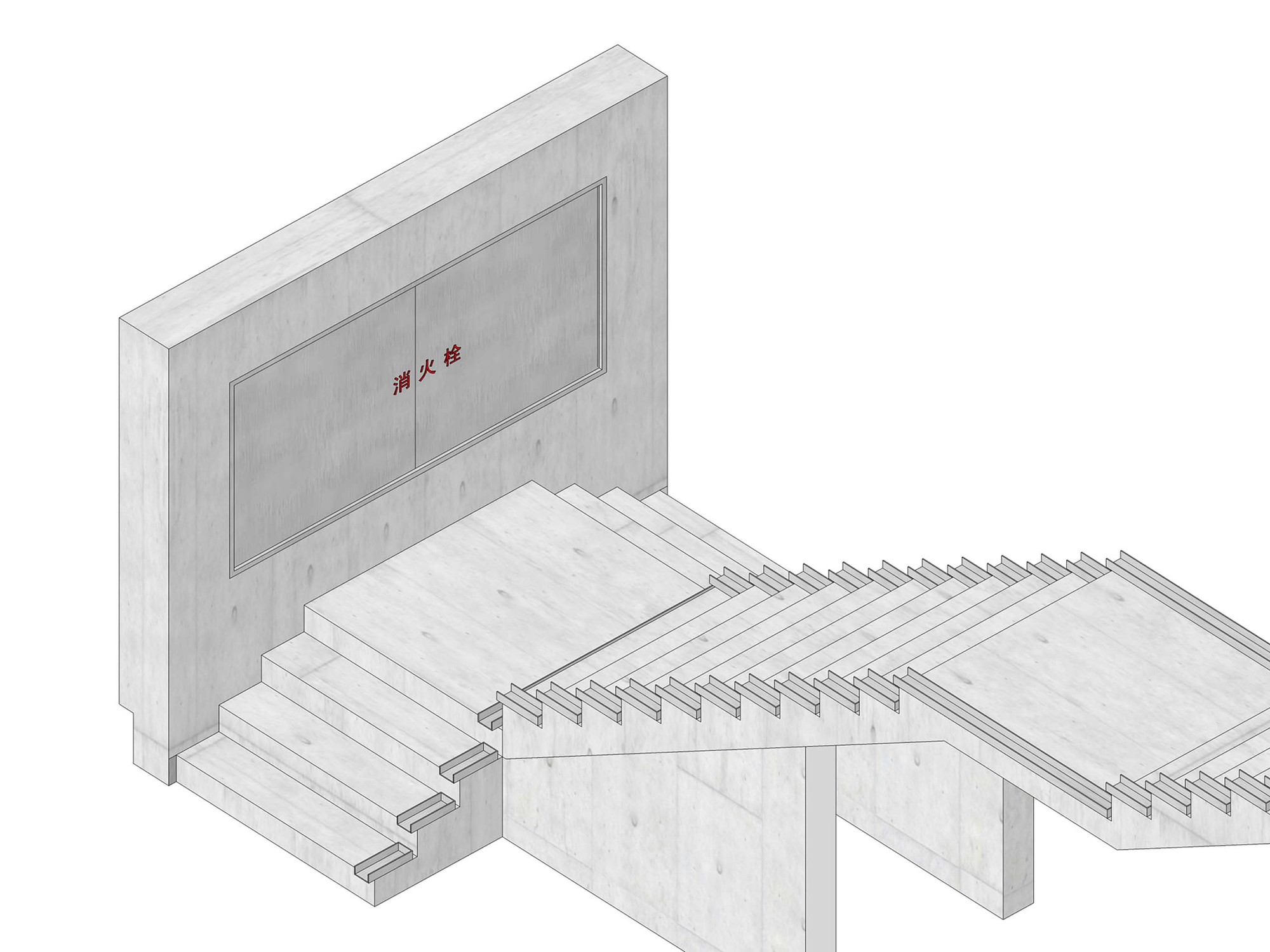

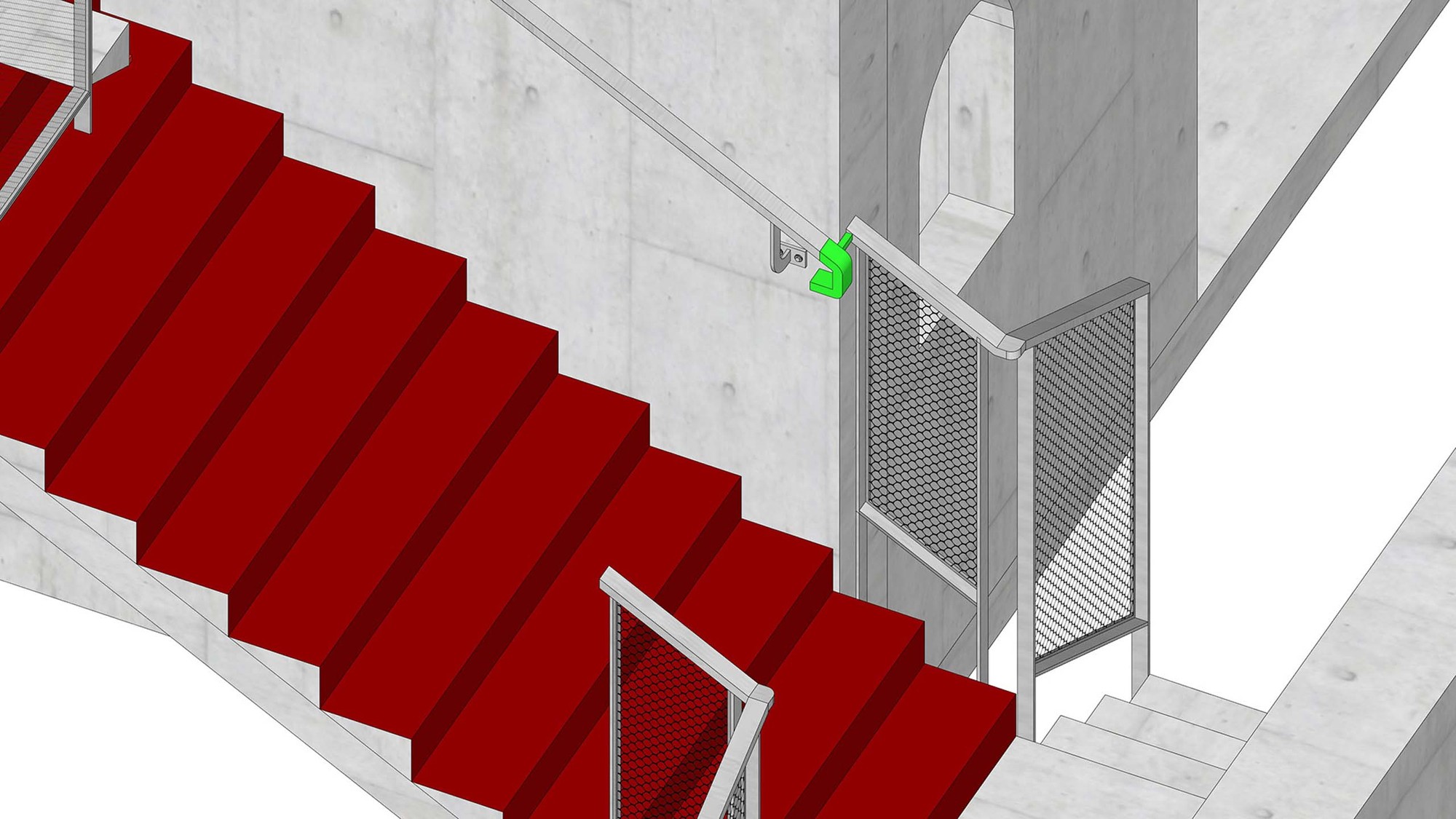

According to the commercial building code, each evacuation staircase must have a fire hydrant, which is particularly boring in our layout, but there is no choice, more than a dozen fire hydrants must be found, so we designed a light wall at the lower entrance of each staircase to hide those fire hydrants, and this light wall makes the staircase space look more subtle, and also becomes an important architectural element in the whole inner courtyard after completion.

Fair-faced Concrete. At the beginning of the project, we were always wavering between doing paint or fair-faced concrete regarding the material of the facade. Although the architects had the desire to do fair-faced concrete, there was already a lot of Aranya and we were prepared not to do it, even-textured paint, silicone paint and washed stone were all under consideration. With the process of construction drawings, due to the special nature of the structure, the parts that can do infill walls on the facade are already minimal, so almost all concrete cast-in-place structure is a foregone conclusion, then it is better not to install it, or to do fair-faced concrete. However, after some arguments about appearance and cost between ordinary plywood or small wooden forms, we finally chose the simpler and cheaper plywood form. The general contractor was very experienced and recommended a 1.8m long special formwork. We separated the façade according to 450 modules and kept communicating with the general contractor about the location of the construction joints and the treatment of complex shapes at the joints.

Vertical wall pouring has no problem, but the pitched roof vibrating will be more complicated, experienced several real samples of pouring experiments, and ultimately can not solve the problem of a small number of bubbles on the surface of the concrete, I later advised the general contractor do not care, as long as the procedure is completely done, bubbles do not matter – since it does not affect any structural, seepage resistance and other issues, the bubbles are also objective and sincere.

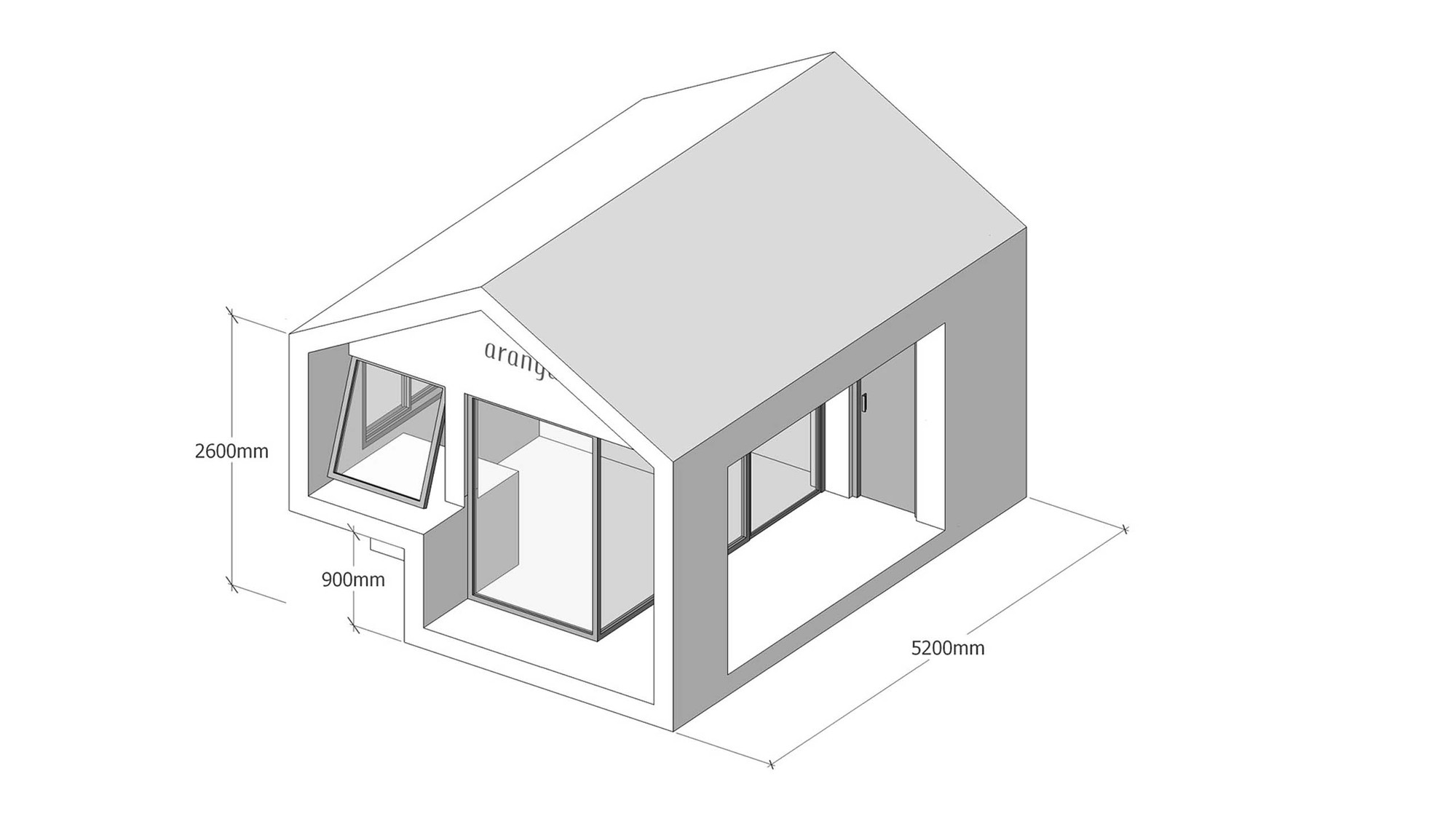

We also did a large scale concrete experiment at the south entrance of Aranya, which was conceptualized as a guest house box that would not go to waste and could be used as a gatehouse for the south entrance in the future. When we poured the pointed roof, we found that we had underestimated the difficulty of pouring this kind of non-horizontal and vertical shape, for example, the “tip” of the house was very difficult to pour and had to be wiped. After discussing technical measures such as whether to prefabricate the roof, I finally gave up on the pointed roof and replaced it with a small flat trapezoidal roof, so the final kennel rooms have two roof shapes, one is a large flat roof and one is a small flat roof.

All the later concrete repair, waterproofing, and seepage resistance as well as internal insulation, solid samples of doors and windows, air conditioning louvers, and railings were passed on this one-to-one large sample and continued to be tested by time in the more than one year of formal construction that followed.

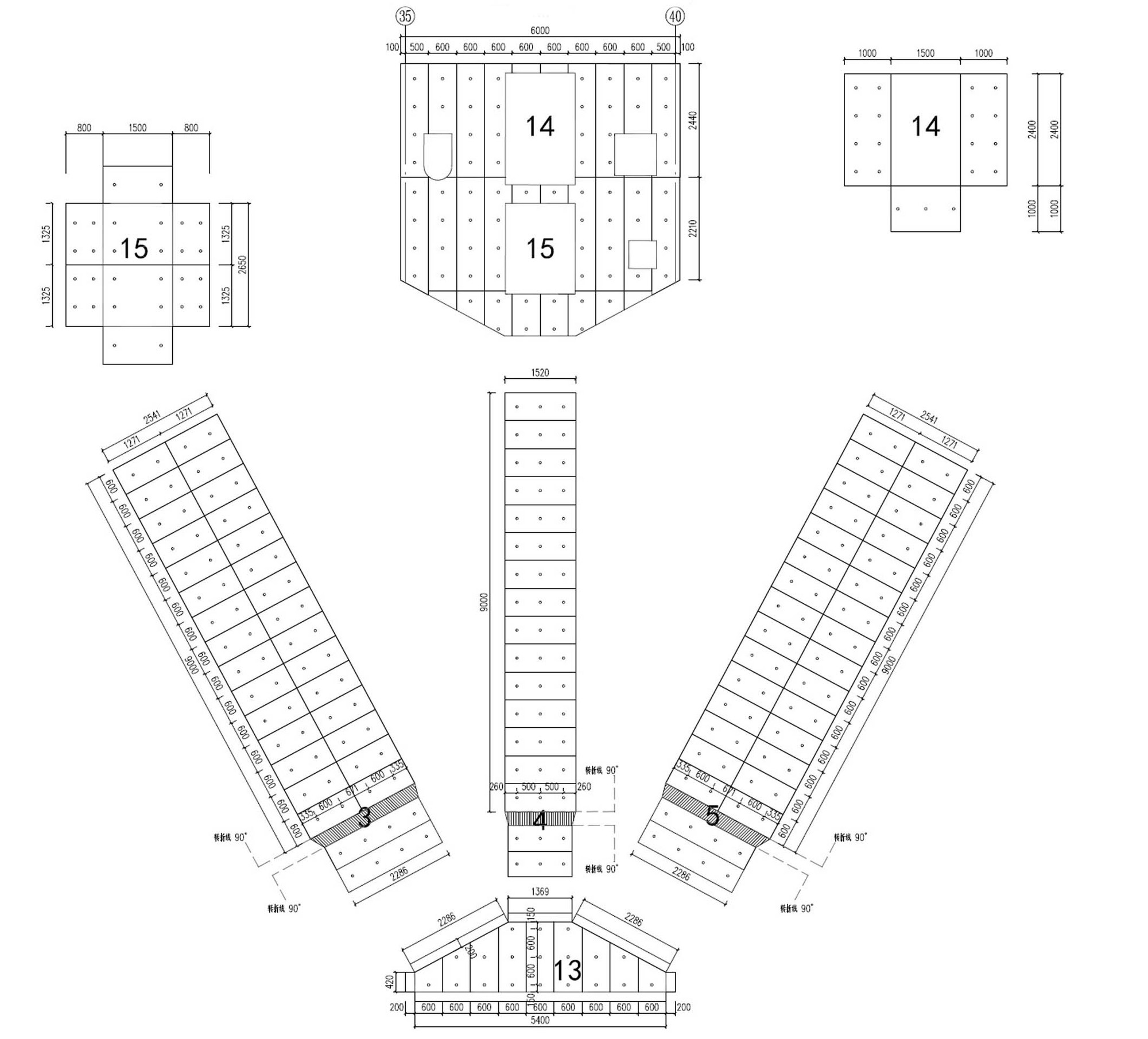

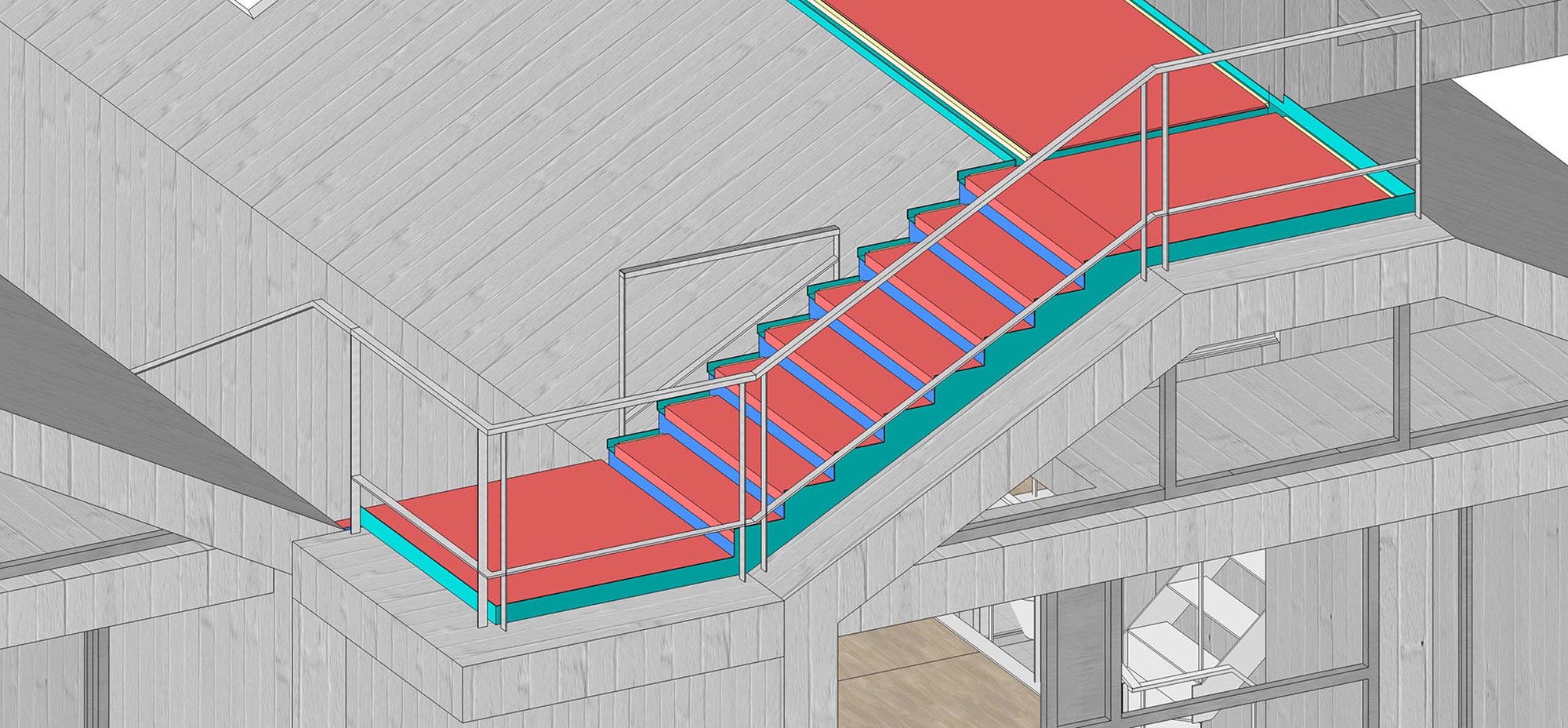

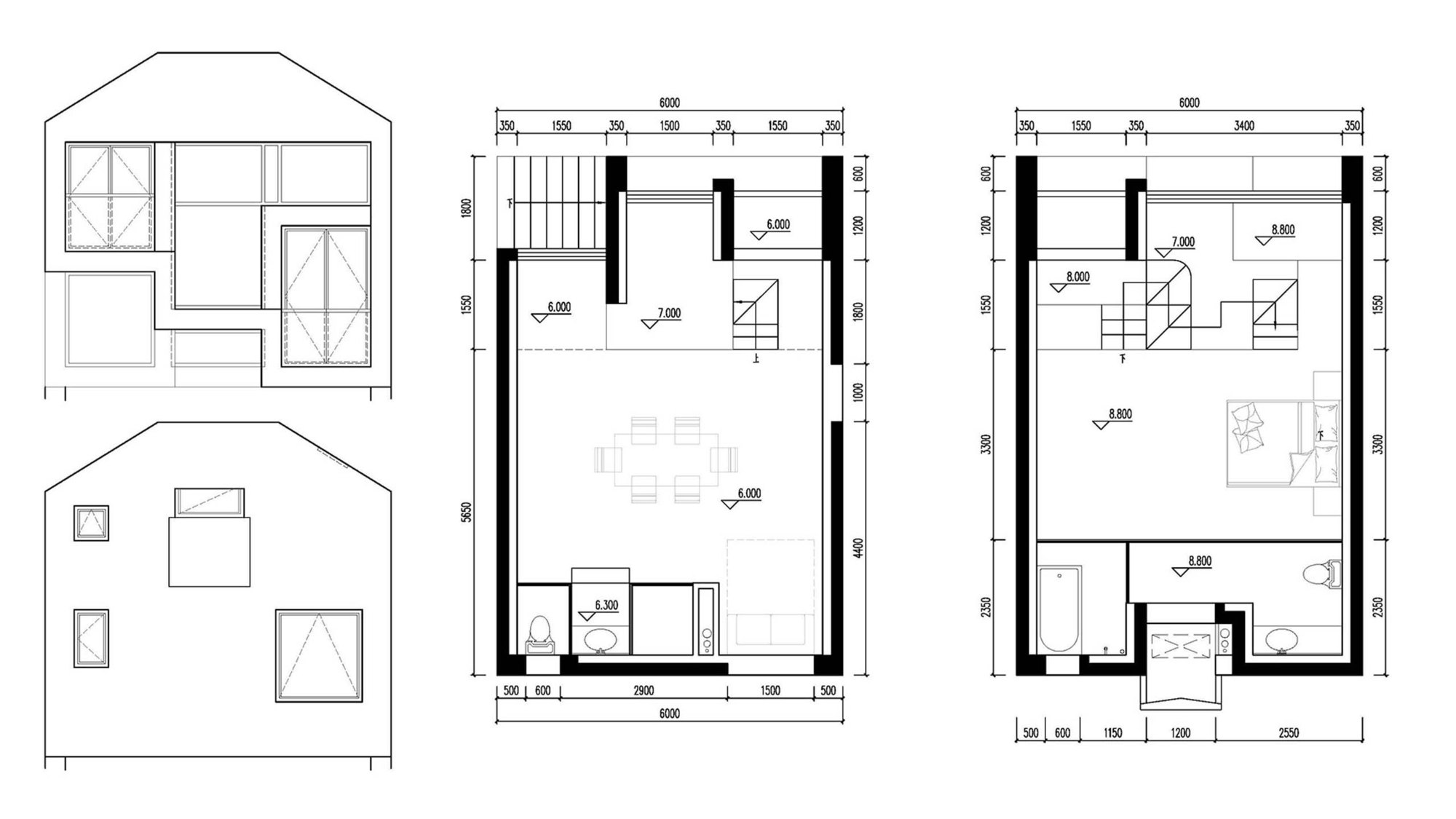

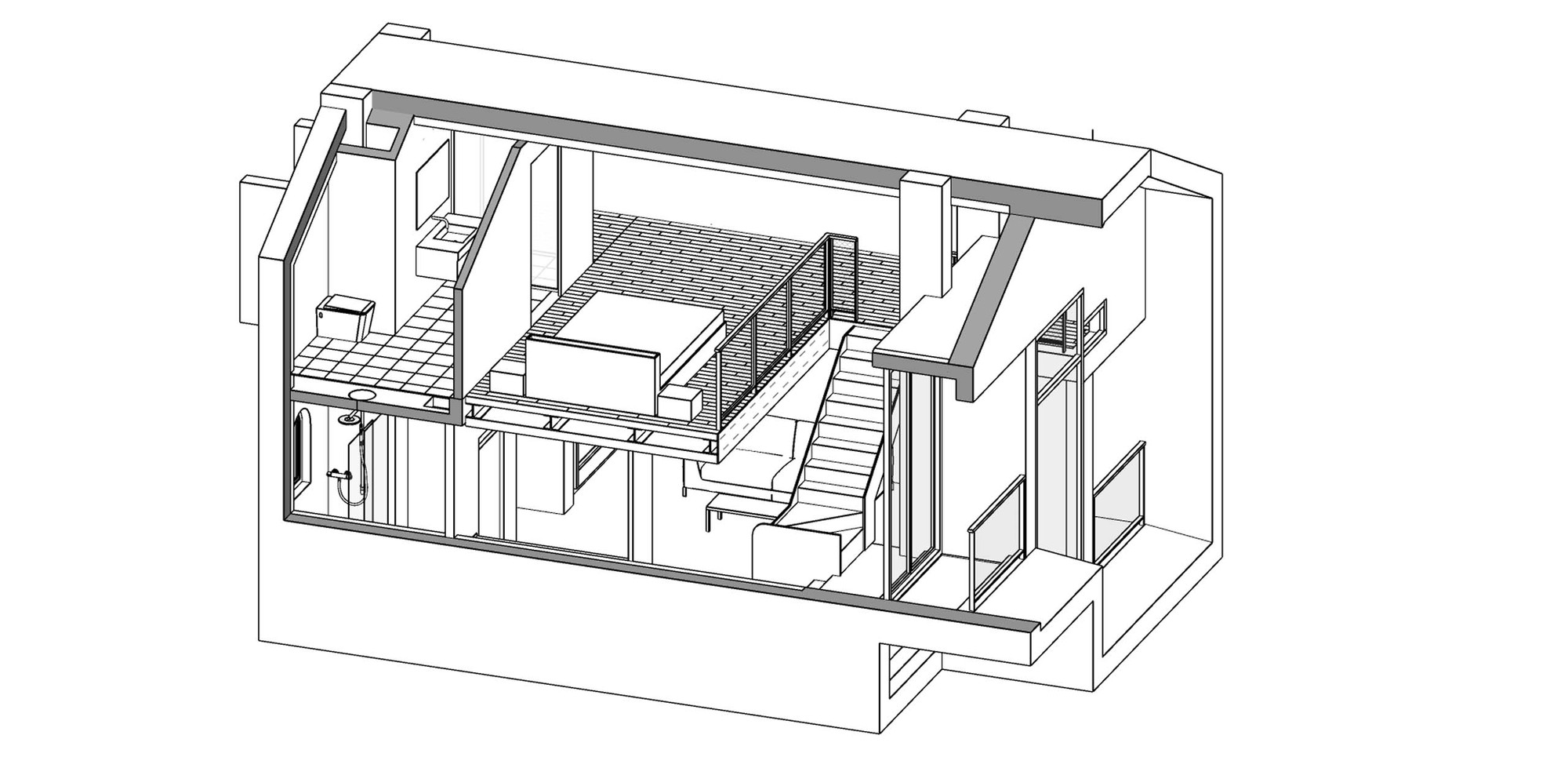

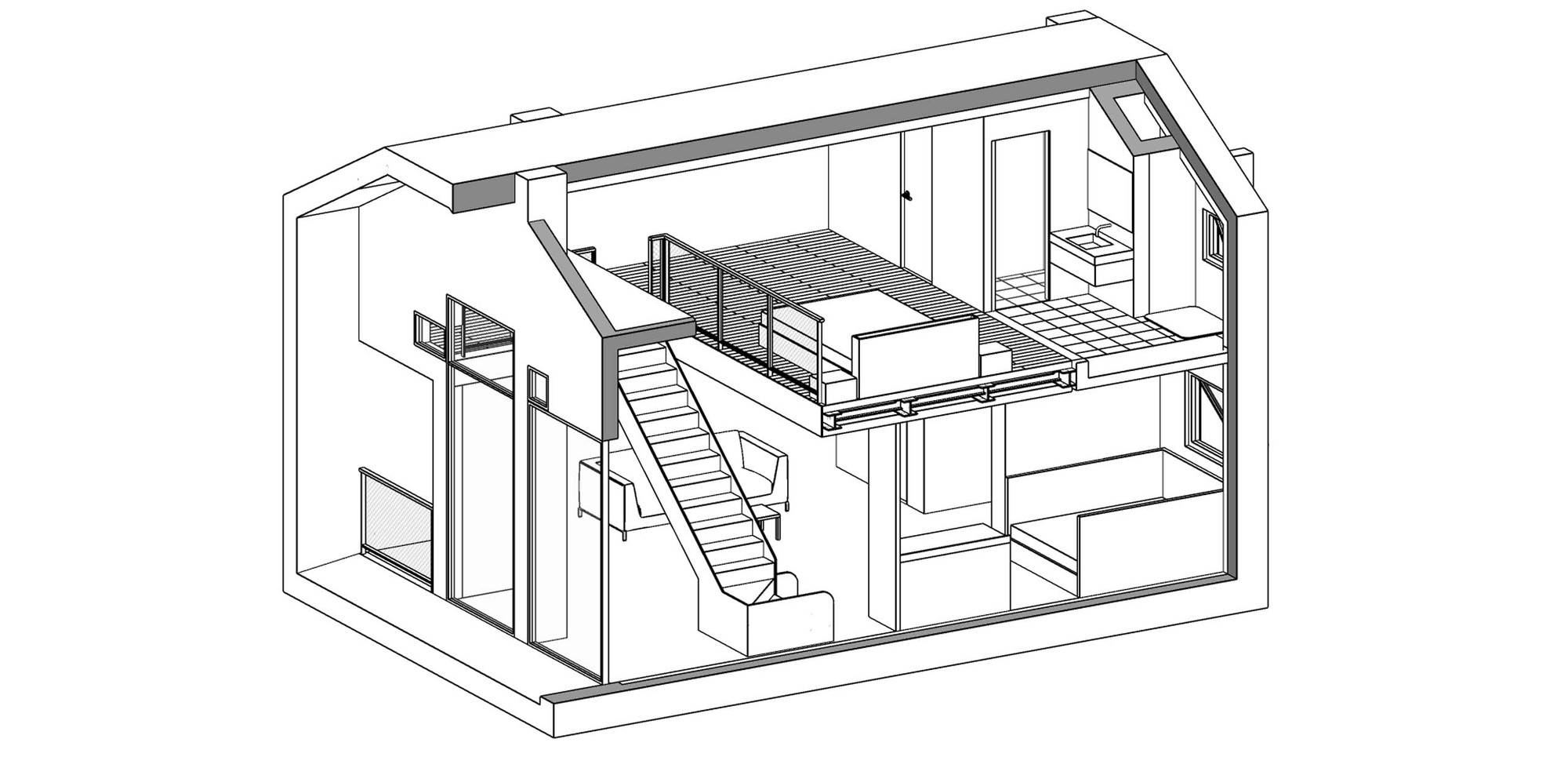

Guest room design. Since the initial design limited the size of each guest room box to a basic type of 6m x 9m, the 30 guest rooms were basically divided into four basic types, with different interior spaces derived from different influences of entrance directions and façade drops under this size control. During the design process, the slight variations in location and access and retreat outside the four basic types led to more design results. As mentioned before, the influence of the outdoor staircase on the shape of the guest room basically determines the direction of the indoor staircase, so the subsequent design of the indoor staircase basically finds the convention on several elevations to calculate the size, so that the staircase becomes an indoor device, not only becomes the core of transportation up and down but also connects several small spaces for people and dogs to produce interesting stops.

The bed was torn between the side and the center, but in the end, the conventional arrangement of the side was chosen. In addition to the large bed upstairs, a tatami space was also arranged downstairs to provide a variety of family structures and human-dog relationships. Both guest rooms have bathrooms, but on the second floor, due to the sloping roof, some of the site dimensions would not be exactly the same as the drawings, so the location of the bathroom and toilet were adjusted before completion to ensure normal human use.

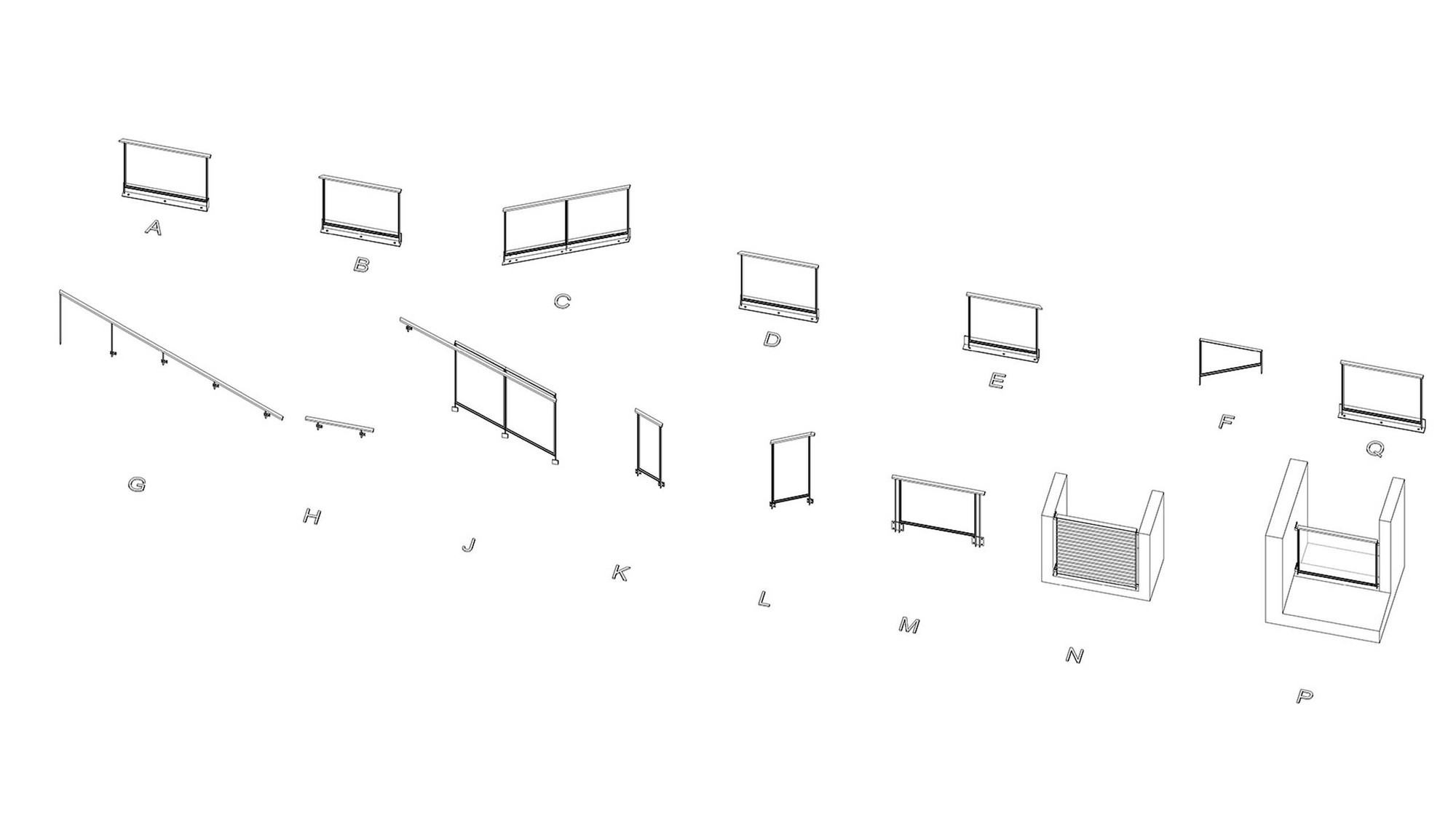

The design of exterior windows is the most complicated process of change, from the first full-opening windows to the later consideration of the installation of curtains and flush opening windows, to the latter due to the upper outdoor staircase fire spacing of 2 meters, resulting in the need to change part of the window position to a step-like solid wall generated by the small window, all “form follows the regulations”. The final presentation is the result of natural evolution according to energy saving, fire protection, cost, and operation factors. In addition to the glass part, the exterior window design also includes an aluminum opening fan to match the 300 modules of the facade.

Waterproofing Design. The slope of the roof of the clear concrete building, the need to slope the visual coherence of the roof and walls, so that the roof waterproofing is much more difficult because the most insurance commonly used coil waterproofing has failed. Then the common practice is to use penetrating crystalline waterproofing agent on the facade concrete under the premise of internal insulation, coupled with its own slope if such a roof waterproofing in the south is basically no problem, but the winter freezing and swelling in the north will make the concrete cracking, then the waterproofing agent will fail. At the repeated prompting of the project manager, I began to look for possible new materials.

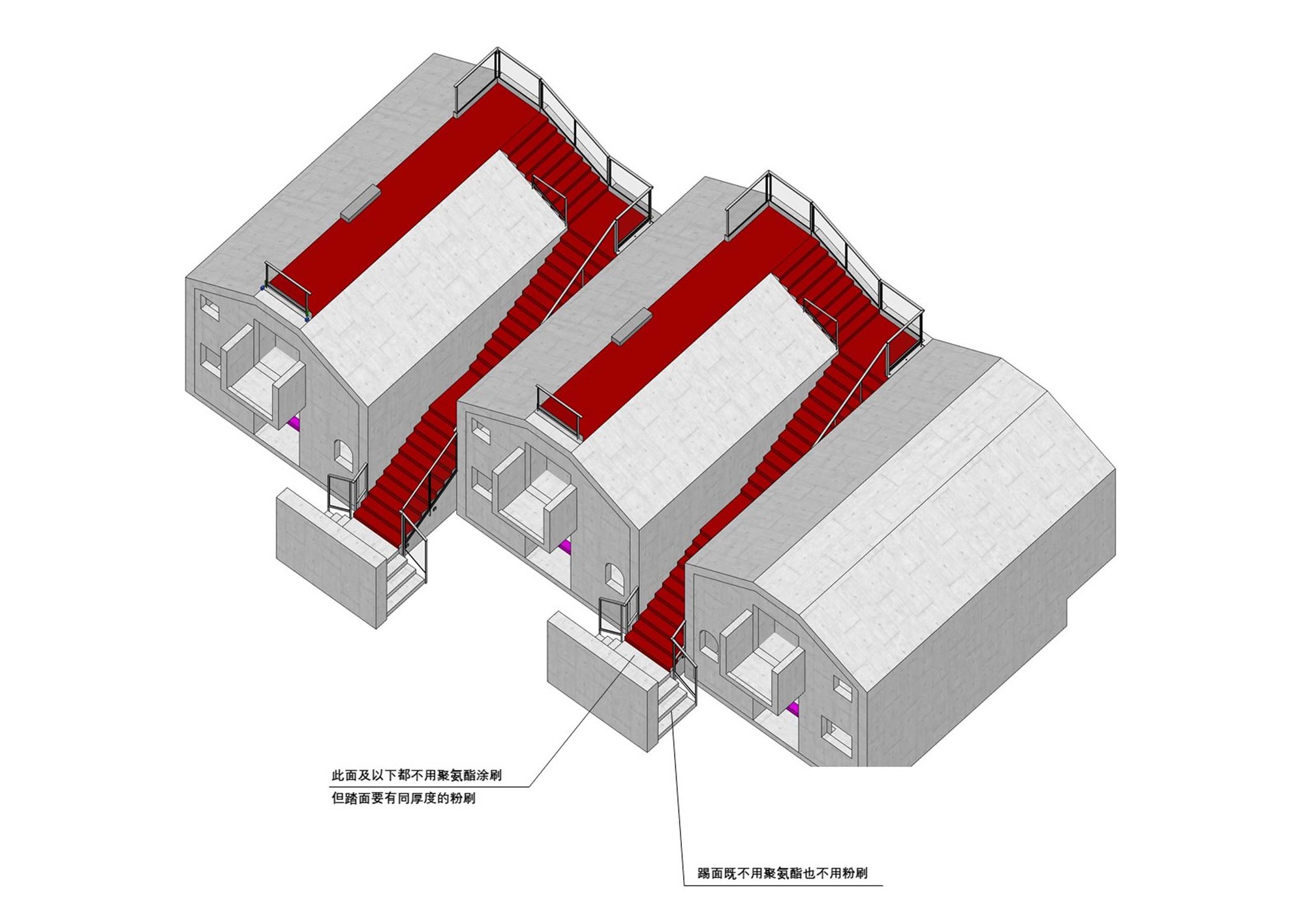

After the transparent matte polyurea waterproofing coating was found, we did a lot of experiments. From small concrete sample blocks to concrete walls and finally the whole experiment on the janitor, we finally settled on this waterproofing material which has never been used on the building facade before. We decided to spray and paint the whole concrete box through and through, just different parts with different thicknesses so that besides waterproofing, it also prevents the corrosive air from the seaside from affecting the life of the concrete, and it also prevents dog urine. Of course, the polyurea had to be applied after all the concrete repair and finishing work was completed.

Before the construction started on the wall, it was still prudent for everyone to start with the roof which was not easily seen. I have written about the story of polyurea yellowing in other articles, so I will not repeat it here. In the end, after all the silicone topcoats for the concrete repair were done, the polyurea still achieved the results we initially set.

When dealing with the staircase part, due to the complexity of the construction process, we first brushed a polyurethane waterproofing coating before the polyurea for insurance purposes, and the mortar protection layer was done once before the polyurea was put on to form a coherent film with the wall, and then finally the stone was laid. After the completion, we also used the way of painting to add paint to the leakage point in the narrow ditch on both sides.

Other parts of the design. Railing design is often easy to be ignored part, those who are not careful to be quoted by the design institute shiny stainless steel railing details and no one feels bad story in the previous government projects repeatedly occur. This time we consider the special climate of the seaside, all the use of brushed stainless steel surface fluorocarbon spraying, and for the perfection of fair-faced concrete, all the use of the practice of post-embedding, for which we also drew a detailed drawing for each embedding practice, and the railing section fully considered the standardized design, which can reduce the probability of worker error.

There is also stainless steel corrugated perforated panels to cover the air conditioning units, stainless steel expansion joint covers custom-made for fair-faced concrete, some small hardware to be rectified after completion, and floor drains with inappropriate elevations due to paving, and even stainless steel air vents bought on Taobao for the general contractor to match the style of the kennels – outside of the backward standard drawings without any sense of design, some unconventional nodes can only be done by the architect.

Conclusion. After the final presentation of the building, people tend to talk about the scheme idea, talk about anthropology, sociology, philosophy, literature, psychology, and other you know all kinds of science, “talk about everything but design”. In fact, design is more about technique, and this boring process about technique is the real beginning of design, which makes the program rich and full. When an architect enjoys the honor, he or she should not forget the assistance and cooperation of the client, local design institute, and constructor. The architect is supposed to do technical work, and technology is also an important condition for the iterative development of architecture, which produces beauty by itself. Since architecture is somehow academically, there must be both theory and practice. Without talking about practice, architecture is void.

On the National Day of 2021, which was also the trial period of the kennels, I took my old dog Diamond and drove more than 2,700 kilometers back and forth to live in Aranya Kennels for five days to examine the building I had designed for three years from the user’s perspective. In the end, Diamond and I were basically satisfied with the design, construction, management, and operation of the kennels.

▼项目更多图片